From Formula to Factory: How is NPK Fertilizer Produced at Scale?

In modern agriculture, NPK compound fertilizer is the “golden formula” for crop nutrition, but few understand the complete process from lab formulation to industrial production. What exactly is the relationship between NPK fertilizer production processes and compound fertilizer production lines? This article reveals this critical transformation process.

1. Basic Principles of NPK Fertilizer Production

The core of NPK fertilizer lies in the scientific ratio of nitrogen (N), phosphorus (P), and potassium (K). Laboratory production typically includes the following steps:

- Raw material selection: Basic materials like urea, ammonium phosphate, potassium chloride

- Formula calculation: Determining N-P-K ratios based on target crop needs

- Mixing process: Physical mixing or chemical synthesis

- Granulation: Improving physical properties and slow-release effects

2. Key Transformations for Industrial Production Lines

Converting lab formulas to industrial production requires consideration of these key factors:

- Scale-up effects: Formulas successful in small tests may face mixing uniformity issues in mass production

- Process equipment adaptation: Manual lab operations need conversion to automated processes

- Cost control: Industrial production must consider economic factors like raw material procurement and energy consumption

- Quality control systems: Establishing full-process inspection standards from raw materials to finished products

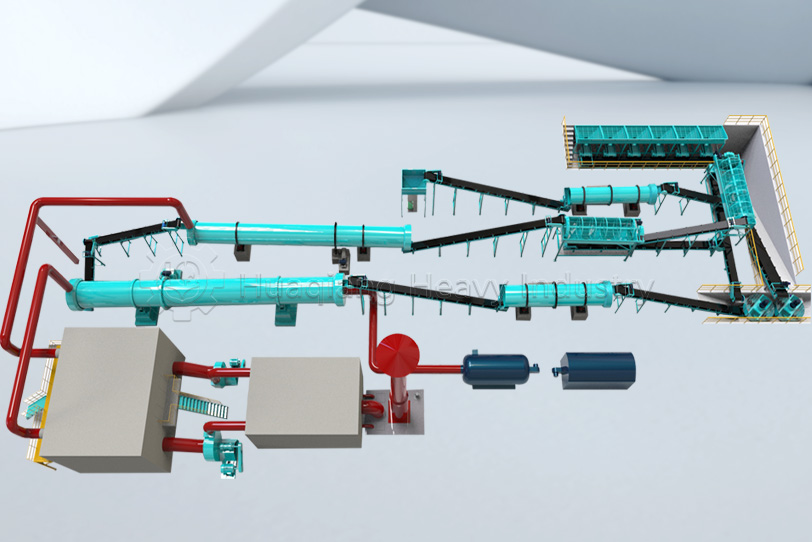

NPK compound fertilizer production line

3. Collaborative Optimization of Production Process and Line

Successful NPK fertilizer production requires perfect coordination between production processes and line design:

- Formula design stageshould consider production equipment performance parameters

- Production line layout should be optimized according to chemical reaction requirements

- Establish a three-stage verification system: “lab-pilot-mass production”

- Use computer simulation technology to predict scale-up effects

According to International Fertilizer Association statistics, optimized collaborative production systems can improve efficiency by over 30% while reducing energy consumption by 15-20%.