Complete Guide to Organic Fertilizer Production

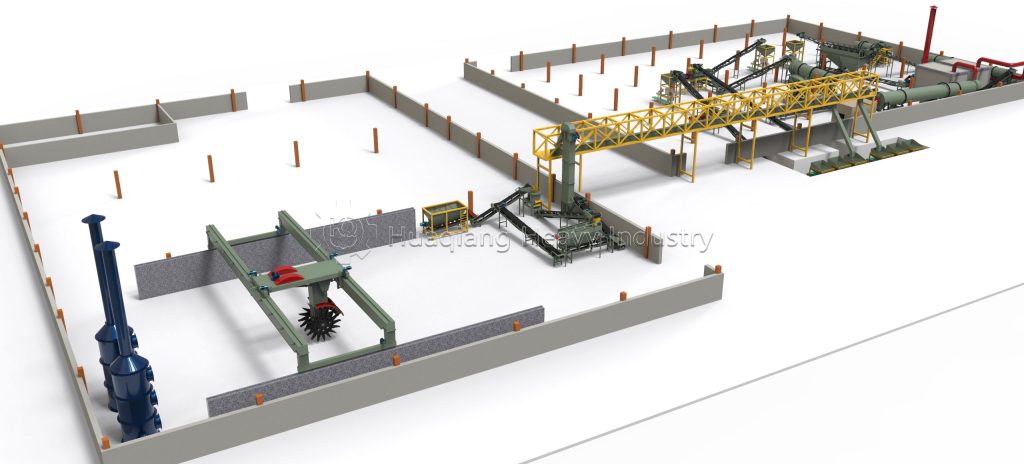

Successful organic fertilizer production relies on specialized machinery to efficiently manage the aerobic fermentation process. The core of this operation involves various compost turners, such as the high-capacity large wheel compost turner for wide windrows or the robust chain compost turner for tougher materials. These machines are fundamental equipments required for biofertilizer production, serving as the primary compost fertilizer machine to maintain oxygen levels, regulate temperature, and accelerate decomposition. This entire phase, encompassing organic fertilizer composting and fermentation, is critical for producing a stable base material. Following this, a fertilizer granulator is often used to form the finished compost into uniform, marketable pellets, completing the cycle from raw organic waste to a valuable soil amendment.

Composting Method: Aerobic Fermentation

Composting is the most common aerobic fermentation method, where microorganisms decompose organic matter in an oxygen-rich environment to create nutrient-rich soil amendment.

Material Preparation

Collect “green materials” (kitchen waste, grass clippings) and “brown materials” (dry leaves, cardboard, straw) in a recommended 2:1 ratio.

Compost Setup

Choose a sunny location and layer materials with each layer about 15-20cm thick. Add a small amount of soil or finished compost to introduce beneficial microorganisms.

Moisture Control

Keep the pile moist but not waterlogged, with ideal moisture similar to a wrung-out sponge. Turn the pile regularly to provide oxygen and promote decomposition.

Maturity Assessment

The compost is ready when it turns dark brown, becomes crumbly, and develops an earthy smell, typically taking 2-3 months.

Fermentation Method: Anaerobic Production

Anaerobic fermentation produces concentrated liquid fertilizer in a sealed environment, providing quick nutritional supplements for plants.

Material Processing

Collect kitchen waste like vegetable peels and fruit residues, clean to remove impurities. Use plastic containers, avoid metal containers.

Fermentation Initiation

For Fermented Plant Juice (FPJ), cover plant material with brown sugar; for other fermented teas, add water with molasses or fermenting agent.

Fermentation Process

Seal the container but leave space for gas escape. Fermentation completes in 1-3 weeks, longer in cooler temperatures.

Usage and Storage

Strain the liquid and dilute at 1 tablespoon/gallon ratio. Remaining solids can be used for composting or directly applied to soil.

Professional Advice: Composting is suitable for improving soil structure, while fermented liquid fertilizer is ideal for quick nutrient supplementation. Both methods can be combined for perfect long-term and immediate effects.

Environmental Benefits

Making homemade organic fertilizers not only reduces organic waste in landfills but also improves soil health and decreases chemical fertilizer usage. This recycling model helps establish sustainable agricultural ecosystems and contributes positively to environmental protection.