From Granules to Industry: In-depth Analysis of Fertilizer Production Line Equipment

With the development of modern agriculture, fertilizer production has become an indispensable part of the global agricultural industry chain. Different types of fertilizer production lines, with their unique process characteristics, equipment configurations, and application scenarios, meet diverse agricultural production needs. This article details four internationally popular fertilizer production lines: compound fertilizer, organic fertilizer, water-soluble fertilizer, and slow/controlled-release fertilizer, analyzing their equipment composition and application scenarios.

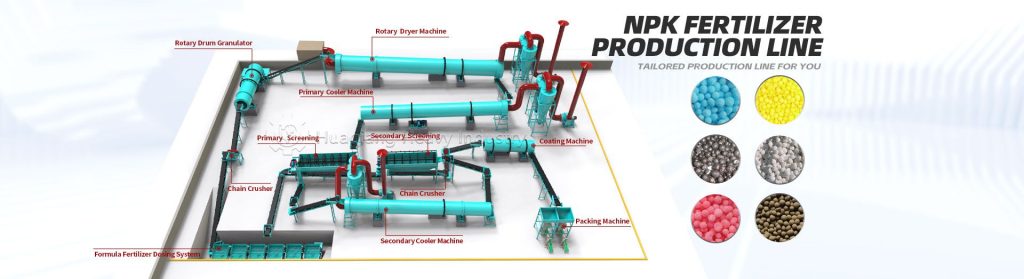

NPK Fertilizer Production Line

Equipment Composition

- Raw material processing equipment:Including crushers and batching machines for crushing raw materials and accurately measuring component ratios.

- Mixing equipment:Such as twin-shaft paddle mixers and V-mixers for thoroughly blending measured raw materials.

- Granulation equipment:Including disc granulators, rotary drum granulators, and extrusion granulators for forming mixed materials into granules.

- Drying equipment:Such as fluidized bed dryers and rotary drum dryers for removing moisture from granules.

- Cooling equipment:Like cooling drums for bringing dried granules to appropriate temperatures.

- Screening equipment:For removing off-spec granules (too large or small) to ensure uniform particle size.

- Coating equipment (optional):For applying a film coating to improve moisture resistance and control nutrient release rate.

- Packaging equipment:Automatic packers for weighing and packaging finished fertilizer.

- Control system:PLC control systems and automation instruments for monitoring and adjusting production processes.

Application Scenarios

Compound fertilizer production lines are suitable for large-scale agricultural production, especially for cereal crops (rice, wheat, corn) and cash crops (cotton, rapeseed). High-tower granulation produces uniform, easily soluble granules suitable for mechanized fertilization, while rotary drum granulation is better for medium-small scale production and various soil conditions[1].

These lines can flexibly adjust NPK ratios to meet different crop needs, making them the most widely used fertilizer production type globally.

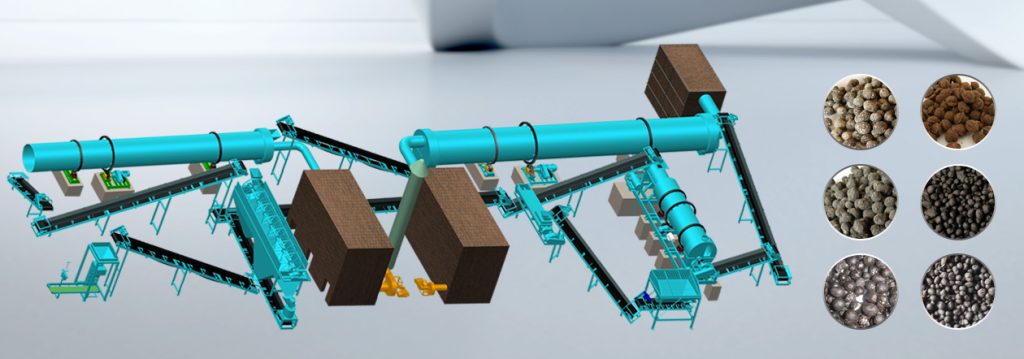

Organic Fertilizer Production Line

Equipment Composition

- Pre-processing equipment:Crushers and screens for breaking down organic waste and removing impurities.

- Fermentation equipment:Composting turntables and fermentation tanks for converting organic waste into stable organic matter while eliminating pathogens.

- Compost turners:For regular turning to provide oxygen and accelerate fermentation.

- Granulation equipment:Disc or drum granulators for forming fermented material into granules.

- Drying equipment:Rotary drum dryers for removing excess moisture.

- Cooling equipment:For cooling granules to prevent quality issues.

- Screening equipment:For ensuring consistent granule size.

- Coating equipment (optional):For moisture-proof coatings.

- Packaging equipment:Automatic packers.

- Control system:PLC systems for monitoring key parameters.

Application Scenarios

Ideal for livestock farm waste treatment, municipal sludge recycling, and green organic farming, especially in facility agriculture, orchards, tea plantations, and high-value cash crop areas[2]. Organic fertilizer improves soil structure and water/nutrient retention, supporting sustainable agriculture.

Bio-organic Fertilizer Production Line

Equipment Composition

- Pre-processing equipment:Crushers and screens for preparing organic materials.

- Fermentation equipment:Turntables and tanks for controlled microbial fermentation.

- Post-processing equipment:Granulators, dryers, coolers, and screens for final product formation.

- Mixing equipment:For blending fermented material with additives like microbial agents.

- Packaging equipment:Automatic packers.

- Control system:PLC systems for monitoring temperature, humidity, and oxygen levels.

Application Scenarios

- Agricultural waste treatment:Large-scale processing of livestock manure, straw, and mushroom residues.

- Environmental upgrades:Helping farms, food waste centers, and processing plants meet environmental standards.

- Fertilizer industry transformation:Supporting organic-inorganic compound fertilizer production or new organic fertilizer plants.

Core value: Transforming pollutants into commercial organic fertilizer meeting NY 884 standards, achieving both environmental compliance and economic benefits.

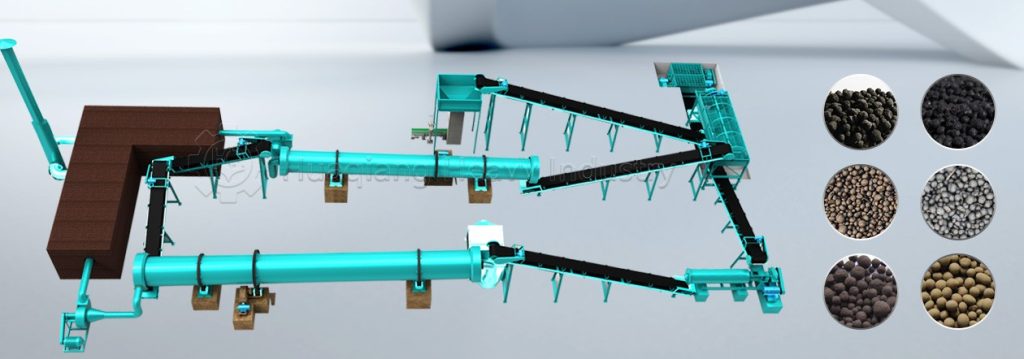

NPK Blending Fertilizer Production Line

Equipment Composition

- Raw material handling system:Silos and conveyors for storage and transportation.

- Batching system:High-precision scales for accurate ingredient measurement.

- Mixing system:Efficient blenders for uniform mixing.

- Cooling and screening system:For temperature control and size consistency.

- Packaging system:Automatic weighing and packing machines.

- Control system:PLC or DCS for automated production control.

Application Scenarios

- Regional formula customization:Quick NPK ratio adjustments based on soil tests and crop needs.

- Low-cost transformation for small-medium fertilizer plants:With equipment costs just 1/3 of compound fertilizer lines.

- On-site blending for large farms:Mobile units for integrated soil testing, blending, and application.

Core advantage: Minute-level formula adjustments at lowest cost to meet precise fertilization needs.

Production Line Selection Recommendations

Consider these factors when choosing a fertilizer production line:

- Target market requirements

- Raw material sources and costs

- Investment scale and expected returns

- Local environmental regulations

- Technical support and after-sales service

With precision and green agriculture development, fertilizer production lines are becoming smarter, more energy-efficient, and multifunctional. Modular design and IoT applications will make production more efficient and sustainable.

References:

[1] International Fertilizer Association (IFA). 2022 Global Fertilizer Production Technology and Market Report

[2] Zhang, F. et al. (2021). Sustainable organic waste management for fertilizer production. Journal of Cleaner Production