Rotary Drum Granulator: Six Processes Revealing the Magic of Granulation

From Powder to Perfect Particles: Exploring the Precision Process Journey of Drum Granulation

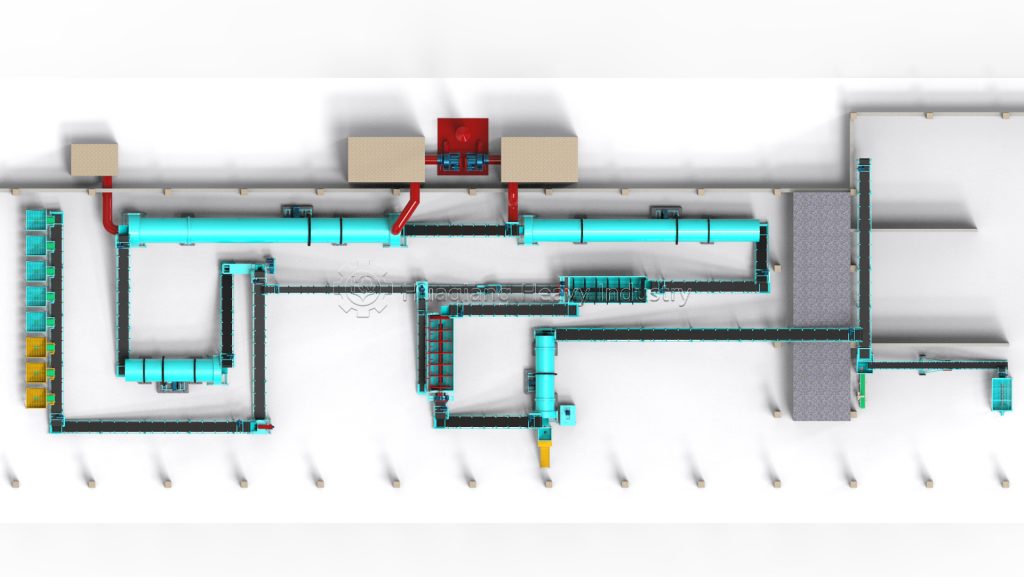

The Perfect Symphony of Precision Processes

The working process of the rotary drum granulator resembles a carefully orchestrated industrial symphony, with six interconnected processes collectively performing the magnificent transformation from loose powder to regular particles. The brilliance of this process lies not only in simple physical changes but in the deep optimization of material characteristics.

Material Pretreatment

Before entering the drum, raw materials require careful “grooming.” Through preprocessing steps like crushing and mixing, material uniformity and appropriate particle size distribution are ensured. Meanwhile, material humidity is precisely adjusted according to process requirements, creating ideal conditions for subsequent granulation.

Precision Feeding

Pre-treated materials are evenly fed into the rotating drum through the feeding port. At this point, the drum interior may have preset suitable humidity conditions or be spraying binders, making full preparations for particle formation.

Rolling and Collision

Inside the drum body, materials move with the drum’s rotation. As the drum tilts and rotates, materials continuously roll and collide inside, gradually forming small aggregates. This process promotes adhesion between materials, laying the foundation for particle formation.

Particle Growth

Small aggregates continuously adsorb surrounding fine powder during rolling and collision processes, gradually increasing and forming particles with certain size and strength. By precisely controlling drum rotation speed, tilt angle, and material humidity, particle growth rate and final size can be accurately regulated.

Spray Humidification

During the granulation process, appropriate amounts of water or binder are sprayed into the drum body through the spray system to maintain suitable material humidity. This crucial step not only promotes particle formation but also ensures uniform particle growth.

Maturation and Discharge

When particles reach expected size and strength, mature particles are discharged from the outlet by adjusting drum speed and tilt angle, then entering subsequent processes such as cooling, screening, or packaging, completing the entire granulation process.

Process Essence: The Art of Dynamic Balance

The core appeal of rotary drum granulator technology lies in its exquisite control of dynamic balance throughout the granulation process. As a versatile fertilizer granulator, parameters such as drum rotation speed, tilt angle, and material humidity interact synergistically, forming a precise balance system that serves both organic fertilizer production line and NPK production line requirements with equal efficiency. The drum granulator‘s rotation creates an ideal mixing environment, its tilt angle determines material residence time, while precise humidity control ensures particle quality stability across various applications.

This physics-based drum granulation method requires no complex chemical additives, relying entirely on precise mechanical control and process parameter adjustment. Unlike the double roller press granulator which employs compression forces, or the mechanical action of a wheel compost turner in preliminary processing, the NPK fertilizer granulator utilizes centrifugal force and tumbling action to form uniform granules. This fundamental difference ensures product purity while achieving efficient production, whether functioning as an organic fertilizer granulator processing biological materials or as part of comprehensive chemical fertilizer manufacturing systems.

The adaptability of this drum granulator technology makes it indispensable in modern fertilizer manufacturing, seamlessly integrating with various preprocessing equipment including the wheel compost turner for organic operations. Its mechanical elegance provides a sustainable granulation solution that maintains material integrity while producing consistent, high-quality fertilizer granules suitable for diverse agricultural applications across both organic and conventional farming systems.

Perfect Embodiment of Innovative Value

The working principle of rotary drum granulators not only showcases the precision beauty of mechanical engineering but also reflects modern manufacturing technology’s deep understanding of materials science. From fertilizer production to chemical raw materials, from food processing to pharmaceutical products, this innovative granulation method is providing more efficient and environmentally friendly production solutions for various industries. Its unique rolling granulation technology ensures excellent product quality, while continuous production processes significantly improve production efficiency. More importantly, the entire granulation process is green and environmentally friendly, with minimal dust generation and excellent noise control, fully complying with modern industrial sustainable development concepts.

Rotary Drum Granulator – Six Processes Forge Excellent Quality, Leading a New Era in Granulation Technology