The Large Wheel Turning Machine: Revolutionizing Compost Processing?

Core Capability: Processes 100-150 tons compost/hour, 1.8-2.5m turning depth, reduces fermentation cycle by 40%

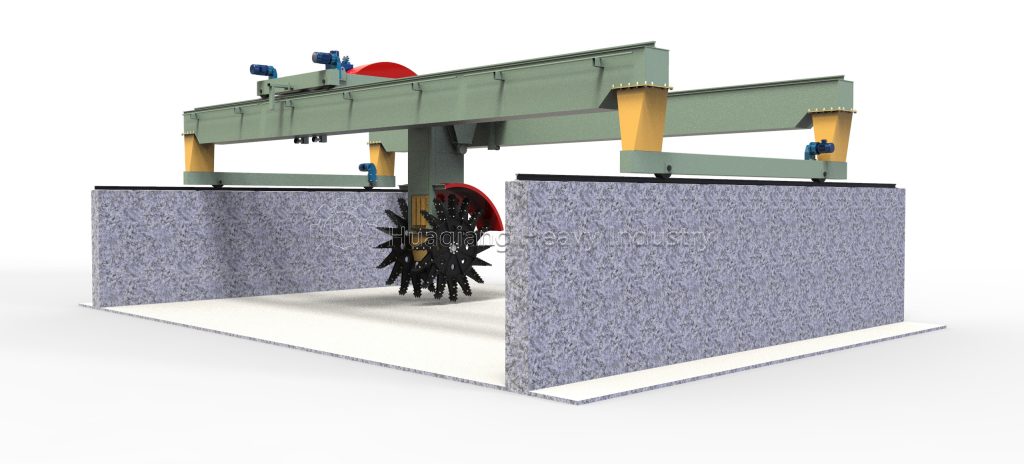

In the world of organic waste management, compost turning machines have emerged as game-changers, with the large wheel turning machine standing out as particularly innovative. These massive rotating systems are transforming composting from an art into a science, accelerating decomposition while requiring significantly less labor than traditional methods. But how exactly do they work, and what makes them so effective?

Power Core: Precision Transmission

The heart of the equipment – the power transmission device – consists of motor, reducer, bearing seat, and main shaft. The motor directly drives the shaft via coupling, delivering stable torque output of 2500-3500N·m. Precision-machined manganese steel flanges ensure firm wheel disc installation, maintaining smooth operation even under heavy loads, with bearing lifespan up to 10,000 hours.

Smart Mobility: Walking System

The walking device features all-gear transmission:

- 5-15kW walking motor adapts to various sites

- Heavy-duty rubber wheels move steadily on soft compost

- ±5° steering accuracy enables precise positioning

This system allows free movement in fermentation channels, handling 6-8m wide material piles.

Height Adjustment: Hydraulic Lifting

The hydraulic system coordinates these components:

- Hydraulic pump provides stable 16-20MPa pressure

- Solenoid valves achieve millimeter-level control

- 2-2m cylinder stroke adapts to different pile heights

Operators can easily adjust turning depth from the cabin with ±2cm precision.

Efficient Turning: Working Device

The turning device uses manganese steel toothed plates:

- 12-18 wear-resistant teeth per wheel disc

- 3-5m material throwing distance ensures complete turnover

- 3x more efficient than traditional equipment

This design ensures full material-air contact, improving oxygen utilization by over 60%.

The Perfect Modern Composting Solution

In organic fertilizer production, the giant wheel turner’s four-system coordination slashes fermentation from 45 to 25 days. This intelligent system delivers unprecedented efficiency with 30% energy savings, becoming essential in modern processing plants. By accelerating decomposition while maintaining quality, it enables higher output of nutrient-rich organic fertilizers. The technology’s precision control optimizes microbial activity, ensuring consistent results batch after batch. As sustainable agriculture grows, these turners are proving vital for scalable, eco-friendly fertilizer production, helping meet global demand while reducing environmental impact.