NPK Fertilizer Production Line: How to Customize a Crop “Nutrition Package”?

In modern agriculture’s pursuit of high yields and quality, NPK fertilizers, which simultaneously provide the three core nutrients of nitrogen, phosphorus, and potassium, are like a “nutrition package” tailored to crops. The NPK fertilizer production line is the specialized workshop that crafts this “package.” It connects multiple types of fertilizer equipment, ensuring precise and efficient production, ensuring that each batch of fertilizer is tailored to the growth needs of different crops.

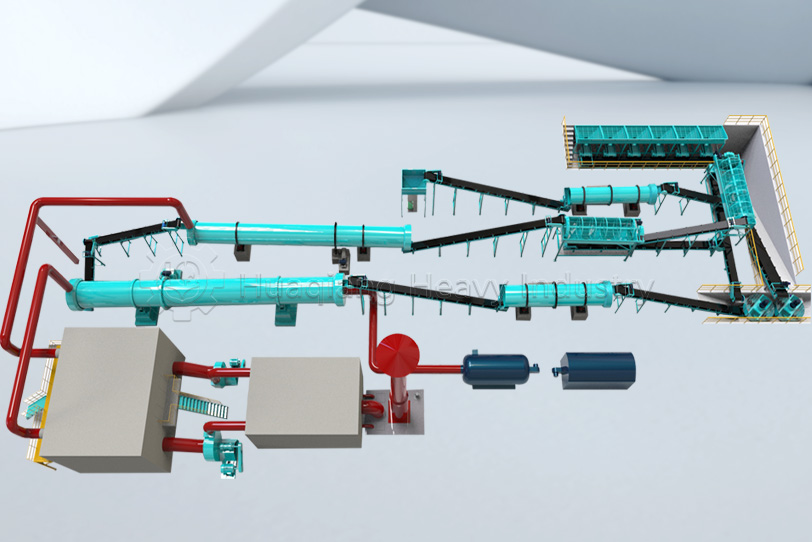

The first step in the production line is “ingredient processing”—raw material pretreatment. Urea, diammonium phosphate, potassium sulfate, and other basic raw materials are first fed into a fertilizer crusher , where bulky raw materials are crushed into fine, uniform particles to prevent nutrient lumps during subsequent mixing. Next, a vibrating screener takes over, acting like a fine sieve to remove impurities and incompletely crushed particles, ensuring that the raw materials meet particle size standards and pave the way for even mixing.

Next comes the “precision meal preparation” phase. An electronic quantitative ingredient scale acts like a precise balance, weighing nitrogen, phosphorus, potassium, and trace elements like calcium and magnesium according to preset recipes (such as those for rice or fruits and vegetables), with an error controllable to within 0.3%. The prepared ingredients are transported via a belt conveyor to the production line’s “core kitchen”—a dual-axis zero-gravity mixer. The mixer’s dual shafts rotate in opposite directions, tumbling the ingredients in a zero-gravity manner. In just 2-3 minutes, the various ingredients are thoroughly blended, ensuring that every spoonful of the mixture has a consistent nutritional profile.

After mixing, the materials enter the shaping and packaging stage. A rotary drum granulator rolls the mixture into round granules with a diameter of 2-4 mm. The granules then pass through a drum dryer to remove excess moisture and a cooler to rapidly cool them down to prevent clumping and deterioration. Finally, an automatic packaging machine accurately measures and packs qualified granules into standard 25 kg or 50 kg bags, which are then transported via a conveyor belt to the finished product warehouse.

Throughout the entire process, a central control system acts as a “master dispatcher,” monitoring the speed, temperature, and output of each device in real time and providing immediate warnings if any anomalies occur. This production line not only enables scalable NPK fertilizer production but also allows for flexible adjustment of formulas to create customized “nutritional packages” for different crops.