Why Bio-Organic Fertilizer Production Lines Are Winning Hearts in Modern Agriculture

In the global wave of agricultural transformation, bio-organic fertilizer production line are gaining unprecedented favor among farmers and investors. This is not merely a choice of production equipment but a profound shift in agricultural philosophy. What exactly makes these complex mechanical systems the new darling of modern agriculture?

The Efficiency Revolution: A Fast Track from Waste to Treasure

Imagine converting organic waste such as livestock manure, crop straw, and food processing residues into high-quality fertilizer. Traditional composting takes months, while modern bio-organic fertilizer production lines require only weeks. This leap in efficiency is the primary reason attracting numerous users.

Key Efficiency Data:

Processing capacity increased by over 300%

Fermentation cycle shortened to 15-25 days

Labor demand reduced by 60-80%

Space utilization improved by 200%

Quality Assurance: The Scientific Appeal of Standardized Production

In an olive grove in Tuscany, Italy, farmer Marco shares his experience: “We used to rely on traditional composting with inconsistent quality. Since installing a complete bio-organic fertilizer production line, every batch has been stable and reliable, significantly improving soil enhancement.”

This quality stability stems from the production line’s precise control:

Intelligent Fermentation System: Precisely controls temperature, humidity, and aeration

Automated Granulation Equipment: Ensures uniform granules with controlled release rates

Closed-Loop Quality Monitoring: Full traceability from raw materials to finished products

Economic Benefits: The Wisdom of Investment Returns

A large farm in Iowa, USA, conducted a detailed economic analysis: investing $1.2 million in a bio-organic fertilizer production line paid for itself within three years through:

Fertilizer Self-Sufficiency: Annual savings of $350,000 on chemical fertilizer purchases

Waste Conversion: Converting farming waste into salable products, increasing annual income by $250,000

Soil Improvement: Crop yields increased by 18%, with quality improvements commanding premium prices

Carbon Credit Trading: Participating in carbon emission trading, earning $80,000 annually

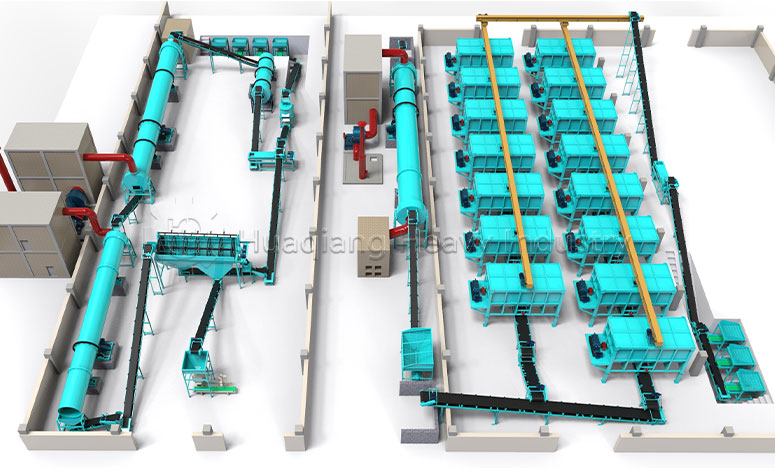

Equipment Synergy: The Appeal of Integrated Solutions

The popularity of bio-organic fertilizer production lines lies in their nature as complete solutions rather than single machines:

Core Equipment Combination:

Preprocessing System: Crushers, sorters, mixers

Fermentation System: windrow composting machine, fermentation tanks, temperature control devices

Post-processing System: new type two in one organic fertilizer granulator, dryers, coolers, screening machines

Packaging and Storage: Automatic packagers, storage systems

Anna, an organic farmer in Bavaria, Germany, notes: “We initially bought only a turner but soon realized we needed a complete production line. The current system, with all equipment working in synergy, is three times more efficient than standalone machines.”

Global Success Stories: Diverse Application Scenarios

Dutch Greenhouse Agriculture Revolution

In modern Dutch greenhouses, small modular bio-organic fertilizer production lines convert pruning residues and nutrient solution waste into specialized fertilizers. This circular system increases water use efficiency by 40% and reduces fertilizer costs by 30%.

Chinese Eco-Agricultural Park

An eco-agricultural park in Zhejiang uses a medium-sized production line to process manure from surrounding livestock farms and crop straw. Producing 20,000 tons of organic fertilizer annually, it not only solves environmental pollution but also generates $5 million in annual output value.

Australian Arid Region Innovation

In South Australia’s arid regions, farmers use solar-powered mobile fertilizer production lines to convert sparse vegetation and animal manure into water-retaining organic fertilizers, significantly improving soil water-holding capacity.