Why does the organic fertilizer production line need a ball shaping machine?

In order to obtain finished fertilizers with more uniform particles, many organic fertilizer production lines use rounding machines. This is because the fertilizer particles made by the fertilizer granulator are relatively rough and not so round. Spherical fertilizers are convenient to use and sell better, so many commodity fertilizer factories will use ball shaping machines to reprocess fertilizer particles.

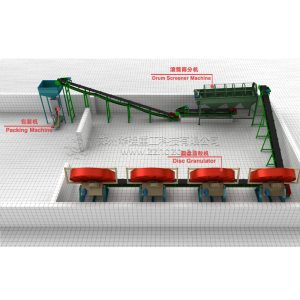

The ball shaping machine has a high output and can be flexibly arranged in the process. It can be used simultaneously with the organic fertilizer granulator and the disc granulator. The rounding machine consists of two or three rounding cylinders arranged in sequence. After the material is rounded several times, the finished product is discharged from the discharge port. The finished product particles have consistent particle size, are round and smooth, and the finished product rate is as high as 97%. A small amount of fertilizer falls from the gap on the edge of the rounding machine and flows out along the waste port. This working principle greatly improves the raw material utilization rate of the rounding machine and increases economic benefits.

The ball shaping machine has a beautiful appearance, simple structure and working principle, is safe and reliable, small in size, light in weight, and easy to operate and maintain. The rounding machine has strong adaptability and can work in various environments. It can maintain continuous operation for a long time, with low power consumption, less electrodes, low production costs and high economic benefits.

The above are the reasons why the organic fertilizer production line needs a ball shaping machine. If you are interested in this, please contact Huaqiang Heavy Industry. We specialize in the production of various fertilizer processing equipment, such as: granulators, crushers, screening machines, turners, etc.