Daily Fertilizer Production Knowledge: Combined Granulator

What is a Combined Granulator?

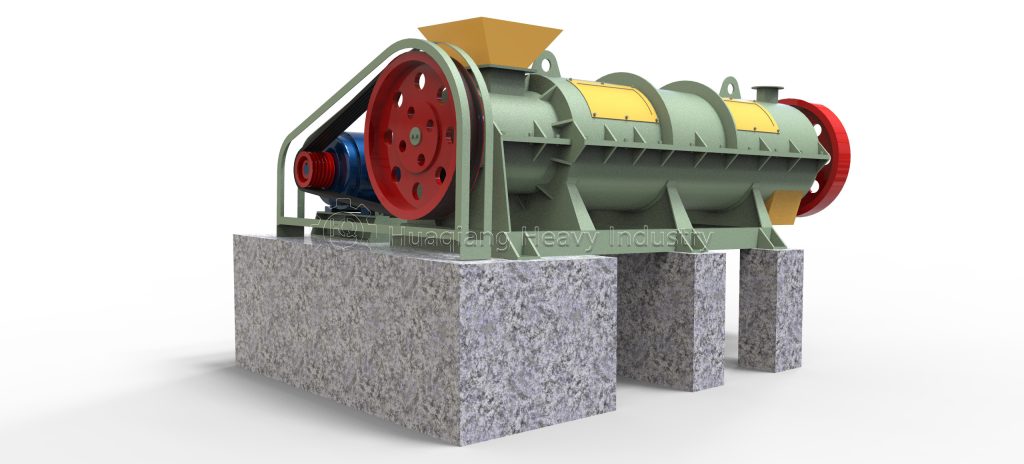

A combined granulator is an advanced equipment integrating multiple granulation technologies, combining processes like drum granulation, extrusion granulation, and spray granulation into one versatile solution. Particularly suitable for complex fertilizer formulations, it automatically adjusts granulation methods based on material characteristics.

The combined granulator is a key equipment in fertilizer production lines, integrating multiple functions like mixing, granulating and polishing in one machine. It significantly improves production efficiency by reducing equipment footprint and energy consumption while ensuring uniform granule quality. Its main advantages include higher output capacity, lower maintenance costs, and better adaptability to various raw materials compared to traditional single-function granulators.

Core Working Principles

- Mechanical-liquid phase synergy: Forms granules through combined mechanical force and binders

- Three-zone design: Continuous process through pre-mixing → granulation → finishing zones

- Smart adjustment: Automatically selects optimal granulation mode for materials

Key Role in Fertilizer Production Lines

Positioned after mixing and before drying processes, combined granulators are central to determining granule quality and production efficiency. Their main functions include:

- Transforming mixed powders into uniform granules

- Improving granulation rate of low-grade materials (exceeding 90%)

- Enabling composite granulation of organic-inorganic materials

- Producing specialty fertilizer granules with controlled-release functions

When to Choose Combined Granulators?

| Application Scenario | Advantages |

| Diverse raw material properties | Auto-adjusts parameters for different materials |

| Specialty fertilizer production | One-step formation of complex functional granules |

| Small-batch multi-variety production | Quick process switching with minimal cleaning |

| Organic-inorganic compound fertilizers | Solves granulation challenges with organic matter |

Technical Advantages and Limitations

Advantages:

- High granulation rate with uniform particle strength

- Reduces equipment quantity and floor space

- 15-20% lower energy consumption than multiple single-purpose units

Limitations:

- Higher initial investment cost

- Requires skilled operators

- Relatively complex maintenance