New choice for dry granulation: roller granulation production line

The double roller press granulator uses a dry granulation process, using a high-pressure roller compactor to compress powdered materials into dense flakes or lumps. These are then crushed and screened to produce uniform granules. Unlike wet granulation processes such as drum granulation and disc granulation, double roller press granulator does not require the addition of liquid binders and allows for a single-step granulation process.

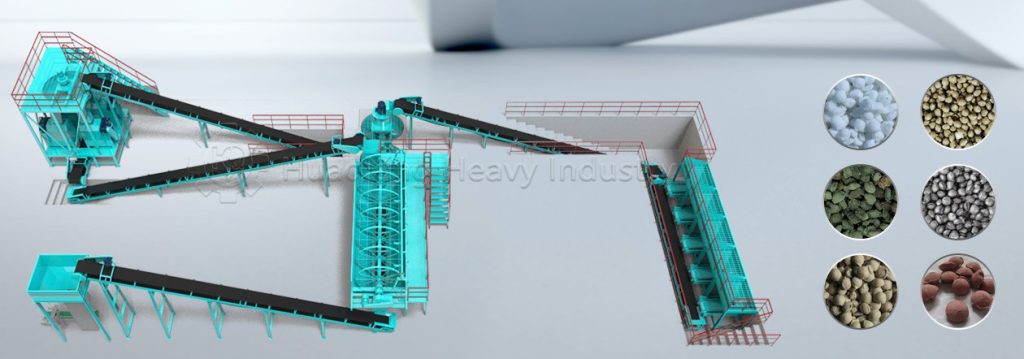

A complete roller press granulation production line mainly has the following steps.

First, the fertilizer is batched by a fertilizer batching machine, then crushed by a fertilizer crusher, stirred in a fertilizer mixer machine , and then put into a double roller press granulator for granulation. The qualified fertilizer particles are dried by a fertilizer screening machine, and then the fertilizer particles are coated and finally packaged.

Working principle

In the roller press granulation production line,the double roller press granulator is the core granulation equipment.The double roller press granulator applies high pressure to powder or granular materials to press them into dense flakes, and then forms uniform particles through crushing and shaping processes.

Advantages

The roller granulation production line adopts dry granulation technology, so compared with the disc granulation production line, the disc granulator production line does not require a fertilizer dryer and a fertilizer cooler, so the investment cost is low, the effect is quick, and the economic benefits are objective.

The fertilizer granules produced by the double roller press granulator can effectively convert these different types of fertilizer raw materials into uniform granules, improving the utilization efficiency and application convenience of fertilizers.