The Complete NPK Fertilizer Production Line Guide

What is an NPK Fertilizer Production Line?

Modern agriculture relies heavily on precisely formulated fertilizers to meet crop nutritional needs. An NPK production line represents a sophisticated industrial system designed to manufacture compound fertilizers containing the three essential nutrients: nitrogen (N), phosphorus (P), and potassium (K). This integrated approach to NPK fertilizer production technology combines precise measurement, thorough mixing, and advanced granulation techniques to create uniform, high-quality fertilizer products that support global food production.

The efficiency of an NPK production process depends on the seamless integration of specialized equipment and precise control systems, working in harmony to transform raw materials into nutritionally balanced fertilizer granules ready for agricultural application.

Key Components of NPK Production Technology

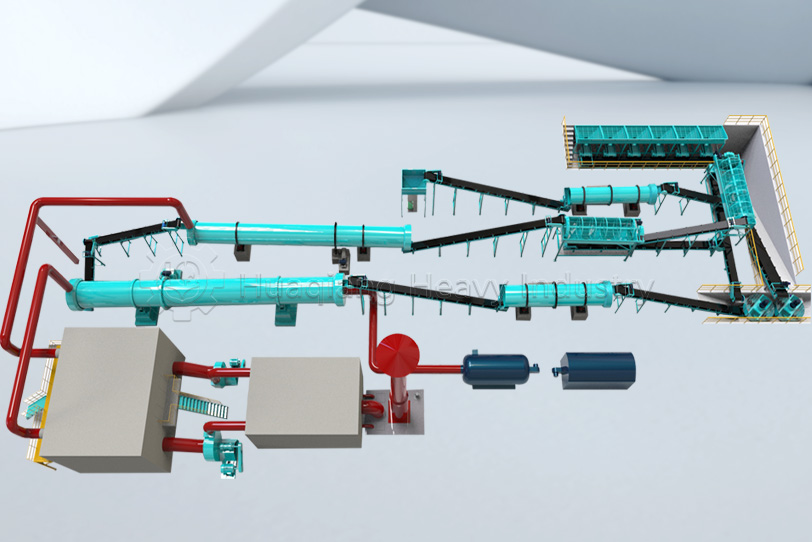

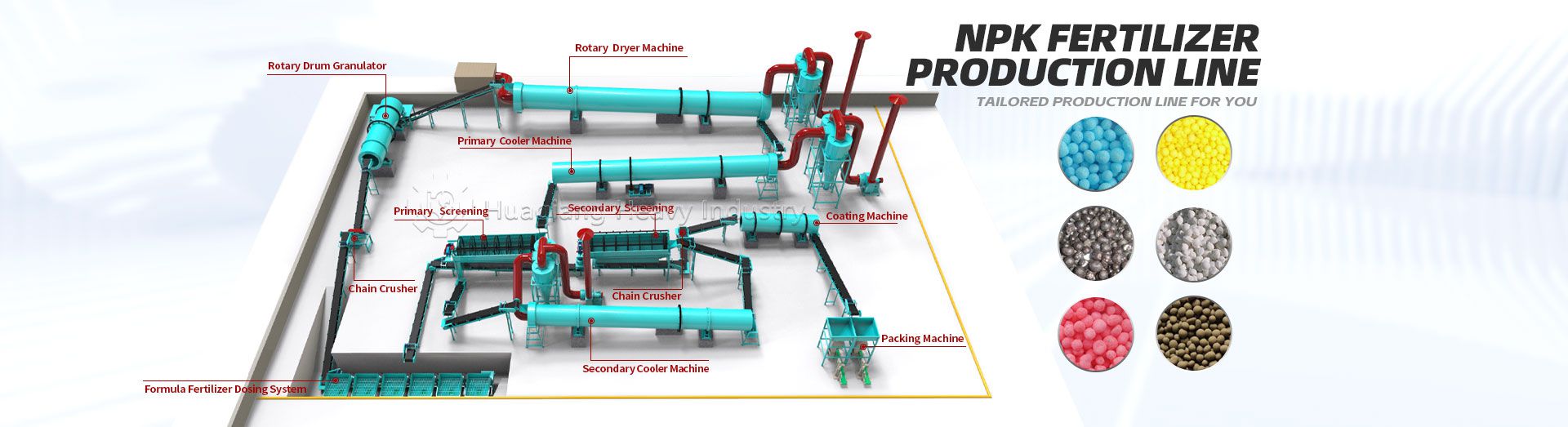

The heart of any NPK fertilizer production process is the sophisticated equipment that handles each stage of transformation from raw materials to finished product. A typical NPK production line includes raw material processing equipment like crushers and batching systems, mixing equipment such as dual-shaft paddle mixers, and the crucial NPK fertilizer granulator that forms the mixed materials into uniform particles.

Beyond granulation, the production line incorporates drying equipment to remove moisture, cooling systems to bring particles to optimal temperature, screening equipment to ensure consistent size distribution, and optional coating machines that enhance product performance. Each component plays a vital role in the overall NPK fertilizer production technology, contributing to the efficiency and quality of the final product.

The NPK Production Process Explained

The NPK production process begins with careful raw material preparation, where ingredients are precisely measured according to specific fertilizer formulas and crushed to optimal size. The mixing stage follows, ensuring homogeneous distribution of nutrients throughout the blend. The mixed materials then enter the NPK fertilizer granulator, where they’re formed into granules through rotation, compaction, or extrusion techniques.

After granulation, the particles undergo drying to remove excess moisture, cooling to stabilize the product, and screening to achieve uniform size distribution. Some advanced NPK production line setups include coating equipment that applies protective layers to granules, enhancing their storage and application properties. The entire NPK fertilizer production process is monitored and controlled by automated systems that maintain precise parameters throughout, ensuring consistent quality and optimal efficiency.

Modern NPK fertilizer production technology has revolutionized agricultural practices by delivering customized nutrient solutions that address specific soil and crop requirements, significantly contributing to global food security and sustainable farming practices.

Advantages of Modern NPK Production Lines

The integration of advanced NPK fertilizer production technology offers numerous benefits. Automated NPK production line systems achieve remarkable efficiency, processing large volumes of material with minimal human intervention. The precision engineered NPK fertilizer granulator ensures product consistency, creating uniform granules with predictable nutrient release patterns.

Furthermore, the flexibility of the NPK production process allows manufacturers to quickly adjust formulas to meet specific regional or crop-specific nutritional requirements. Environmental considerations are also addressed through energy-efficient designs and dust control systems integrated into modern NPK fertilizer production process layouts. This combination of efficiency, precision, and adaptability makes contemporary NPK production line installations invaluable assets in the agricultural value chain.