From Waste to Black Gold: Decoding the Modern Bio-organic Fertilizer Production Line

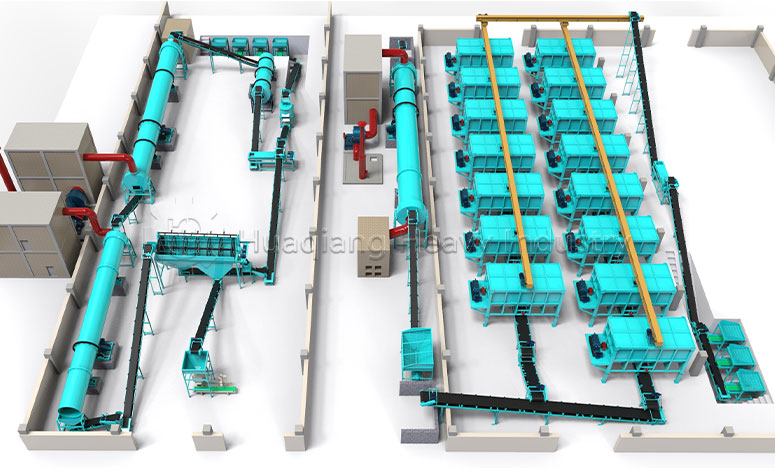

In the wave of green agriculture and the circular economy, bio-organic fertilizer, a star product that combines soil remediation with crop nutrition, is undergoing a profound transformation in its production—from extensive composting to industrial intelligent manufacturing. A well-designed modern bio-organic fertilizer production line is not merely a physical processing line but a controlled ecosystem. It perfectly integrates agricultural waste, livestock manure, and functional microorganisms, ultimately transforming them into high-value “black gold.”

Core Process: A Precise Chain Integrating Physical, Chemical, and Biological Technologies

The modern production line transforms traditional fermentation experience into quantifiable, controllable, and standardized processes. Its core workflow can be divided into four precisely connected stages:

Stage 1: Raw Material Pre-processing & Formulation

This is the “outpost battle” of the production line. Various raw materials (e.g., livestock manure, straw, mushroom residue, distiller’s grains) are gathered via loader feeding hoppers and powerfully crushed by a chain crusher to overcome the challenge of clogging from wet, sticky materials. The crushed material is then uniformly mixed with functional microbial agents and conditioners in a double shaft mixer, ensuring the inoculant makes full contact with every part of the raw material, laying a homogeneous substrate foundation for efficient fermentation.

Stage 2: High-Efficiency Aerobic Primary Fermentation

This is the “heart” of the entire line and the core of biological transformation. The well-mixed material is evenly spread into fermentation troughs by a spreader. Here, the hydraulic trough turner performs automated cruising operations according to preset programs. Through turning, it oxygenates the pile, regulates temperature and moisture. Its high-efficiency operation ensures the uniformity and effectiveness of the fermentation process. An intelligent aeration system at the trough bottom assists with ventilation based on sensor data, together creating the optimal environment for microbial proliferation. Within 10-15 days, preliminary maturation, harmless treatment, and pathogen inactivation of the material are achieved.

Stage 3: Curing & Secondary Conversion

The material from primary fermentation is transferred to a curing area for 20-30 days of static or dynamic curing. During this stage, the microbial community enters a more stable phase of secondary metabolism, synthesizing large amounts of stable organic matter like humic acids, completing the “post-ripening” of the fertilizer, making its effects more gentle and long-lasting. The curing process can utilize large angle belt conveyors for efficient spatial transfer and stacking.

Stage 4: Refined Processing & Finished Product Packaging

The fully matured material becomes base organic fertilizer and can be further processed based on market demand. It is first precisely graded by a rotary screener; oversize material is returned for crushing, while the fine powder can be sold as powdered fertilizer or sent to the next stage. If granulation is required, the material enters a disc granulator or drum granulator with binders. The granules then pass through a dryer and cooler to stabilize their properties, are graded again by a screening machine, and finally sealed by an automatic quantitative packaging machine as finished products ready for the market.

Core Advantages of the Production Line: Intelligence, Efficiency & Resource Recovery

Closed-Loop Clean Production: From raw material reception to finished product dispatch, the entire process features enclosed or negative-pressure design, equipped with advanced dust and odor removal systems, minimizing environmental impact and achieving true green manufacturing.

Digital Intelligent Control: The production line’s central nervous system integrates PLC/DCS automatic control systems, monitoring key parameters like temperature, humidity, oxygen levels, and output at each stage in real-time, enabling digital management and traceability from formulation and fermentation to packaging.

Efficient Resource Conversion: Precise process control maximizes the conversion rate of waste into product. The final product boasts high organic matter content, strong microbial activity, and stable fertilizer efficiency, achieving high-value utilization of waste.

Modular & Flexible Configuration: The production line can be flexibly configured and modularly expanded based on raw material characteristics, investment scale, and product positioning (powder/granular, standard/premium), offering strong adaptability.