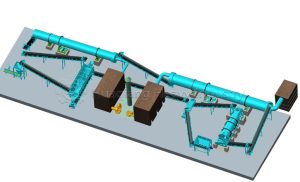

Equipment configuration for farmers to create small fertilizer manufacturing plants

There are too many things that farmers need to worry about, such as the growth status of poultry and livestock, sales, and the treatment of excrement. The only problem is the treatment of excrement. There is no place to discharge it and it is very easy to rot and ferment. The stench is overwhelming, which seriously affects the surrounding living environment and is often complained about. What to do? Don’t worry, the excrement can be made into high-quality organic fertilizer after simple treatment. What equipment is needed to create a fertilizer manufacturing plants?

1. Fermentation equipment. The most important process in the production of organic fertilizer is fermentation, and the excrement must be thoroughly fermented and decomposed.

Common fermentation equipment includes trough-type composting machines, crawler composting machines, chain-plate composting machines, roulette composting machines, fermentation tanks, etc.

The composting machine mainly replaces manual composting, and cannot improve the fermentation process. The fermentation cycle is about 35-60 days, and it occupies a large area. The fermentation tank can greatly improve the fermentation efficiency. The fermentation cycle is generally about 7 days, and it occupies a small area. The disadvantage is that the equipment investment cost is higher than that of the composting machine.

2. Feeder. After the excrement is thoroughly fermented and decomposed, it can be called organic fertilizer. It can be piled up in the decomposition area of the fertilizer manufacturing plant first, and when there is a demand, it can be transported to the feeder for temporary storage by a forklift or conveyor belt.

3. Crushing equipment. After fermentation and decomposition, there will be some lumps, and the application effect is not good, so it needs to be crushed.

4. Screening equipment. It is best to use a screening machine to screen the crushed organic fertilizer, and crush the unqualified large granular organic fertilizer again.

5. Packaging equipment. If the organic fertilizer is for self-use or sold in bulk, packaging equipment can be omitted.

The above equipment configuration is a powdered organic fertilizer production line, which is suitable for farms with a daily output of 5-10 tons of excrement; if the daily output of excrement is more than 10 tons, it is recommended to configure a granular organic fertilizer production line. If you also want to build your own fertilizer manufacturing plant, please contact Huaqiang Heavy Industry.