How to choose the right dehydration equipment according to the humidity of raw materials?

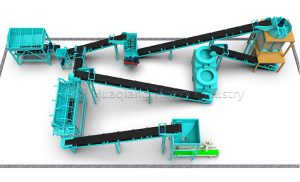

In the field of fertilizer production, raw material humidity is a key factor affecting production efficiency and product quality. Reasonable selection of dewatering equipment is crucial to the construction of efficient organic fertilizer production line, smooth fertilizer production line and to ensure the stable operation of fertilizer granulator.

For organic raw materials with high humidity, such as fresh livestock and poultry manure, the water content is often as high as 70% or 80%. For this kind of raw materials, rotary dryer is the ideal choice. The cylinder body of the rotary dryer is long, and the internal copying board constantly turns the material, so that the wet material is evenly heated and the water is quickly evaporated. In the organic fertilizer production line, it can effectively handle a large number of high-humidity raw materials, creating good conditions for subsequent fermentation, granulation and other processes. Moreover, by adjusting the cylinder speed, temperature and other parameters, the degree of dehydration can be accurately controlled to meet the requirements of different production processes on the humidity of raw materials, ensuring the compact rhythm of the entire production line and efficient coordination.

If the humidity of the raw material is at a moderate level, such as some composted materials, the belt dryer is more advantageous. The belt dryer uses multi-layer conveyor belt, and the hot air penetrates the mesh belt and fully contacts the material, taking away the moisture layer by layer. The energy consumption of this equipment is relatively low, the drying process is mild, and the nutrients in the raw materials can be retained to the maximum extent, which is conducive to improving the quality of organic fertilizers. In the fertilizer production line, the material treated by the belt dryer has a complete particle structure, which provides a good raw material basis for the fertilizer granulator and improves the success rate of granulation and the yield.

Vibrating fluidized bed dryers are a good choice for low humidity raw materials or for situations where only slight humidity is needed. It makes the material jump forward in the fluidized bed through the vibration motor, and is fully mixed with the hot air to accelerate the evaporation of water. The vibrating fluidized bed dryer has the characteristics of high drying efficiency and small footprint, which can quickly complete the micro-dehydration work, ensure that the raw material humidity is accurately adapted to the subsequent fertilizer granulation process, and make the entire production process closely connected and efficient operation.

In short, the selection of suitable dewatering equipment according to the humidity of raw materials is a key measure for fertilizer manufacturers to optimize the production process, improve product quality and enhance market competitiveness, and help your company move forward steadily on the road of fertilizer production.