How to choose the right granulation machine according to the production scale?

In the field of fertilizer production, it is crucial to choose the granulation machine suitable for your own production scale. For organic fertilizer production lines, according to different production needs and scales, choosing the right granulation machine can not only improve production efficiency, but also ensure the optimal control of product quality and production costs. So, in the face of the dazzling granulation machine on the market, how should we choose?

With its compact structure and easy operation, the roller extrusion granulator has become the first choice for small organic fertilizer production lines. It extrudes the material into the desired particle shape by means of two rollers that rotate relative to each other. This method of granulation does not require the addition of water, so it is particularly suitable for the treatment of materials with low water content and easy molding. For small production lines with an annual output of thousands of tons to tens of thousands of tons, the roller extrusion granulator can not only meet production needs, but also reduce machine investment and operating costs.

Flat mold granulator is more suitable for medium scale organic fertilizer production line. It uses a flat die as a molding mold, and forms columnar particles through the extrusion and friction of the material in the die hole. Compared with the roller extrusion granulator, the flat die granulator has a higher molding rate and a more regular particle shape. In addition, it can effectively handle some high-fiber, difficult-to-form materials, providing more flexibility for medium-scale production lines.

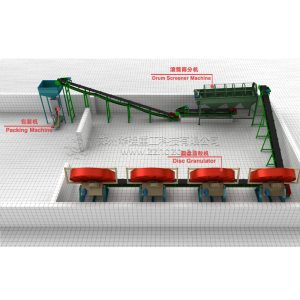

When the production scale is further increased, the drum granulator becomes a more suitable choice. The drum granulator gradually rolls the material into spherical or cylindrical particles through internal mixing and rolling. It has the advantages of continuous production, large yield, uniform particles, etc., which is very suitable for the needs of large-scale organic fertilizer production lines. Although the initial investment of the drum granulator is relatively high, its stable performance and long service life make it significantly cost-effective in long-term operation.

To sum up, the selection of granulation machine suitable for production scale requires comprehensive consideration of material characteristics, production scale and cost effectiveness. For small production lines, the roller extrusion granulator is an economical and practical choice; Medium production line can consider flat mold granulator; For large production lines, drum granulator is undoubtedly a better choice.