In what ways does the screen affect the quality of fertilizer?

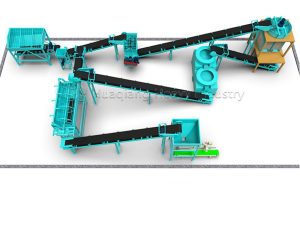

Screener machine is an indispensable key equipment in fertilizer production, whether it is an organic fertilizer production line, or all kinds of fertilizer production lines, and even when used with fertilizer granulator, it has a crucial impact on fertilizer quality.

In the organic fertilizer production line, the raw material sources are wide and the composition is complex. The sifter can effectively remove large particles of impurities in raw materials, such as insufficiently decomposed branches, stones, etc. This process ensures that the organic material entering the subsequent fermentation and processing process is uniform in particle size, provides a good growth environment for microorganisms, promotes the smooth progress of the fermentation process, and thus improves the nutrient content and quality of the organic fertilizer. For example, if a large number of coarse particles are included in the raw material, it will not only affect the fermentation efficiency, but also may lead to caking in the final fertilizer product, affecting its market competitiveness.

For the fertilizer production line, the sifter plays an important role in the combination of chemical fertilizer and organic fertilizer. In the fertilizer production process, the particle size of different raw materials is very different, and the sifter can screen and separate too large or too small particles that do not meet the requirements. Through accurate particle size classification, to ensure that all kinds of raw materials in accordance with the appropriate proportion of uniform mixing, so that the production of compound fertilizer nutrient distribution more balanced. Taking the combination of nitrogen fertilizer, phosphate fertilizer, potassium fertilizer and organic fertilizer as an example, the sifting function can effectively ensure that the particle size interval of each nutrient element is consistent, avoid the uneven release of nutrients caused by particle size difference, and thus improve the utilization rate of fertilizer and extend the fertilizer effect period.

When used in conjunction with the fertilizer granulator, the role of the sifter should not be underestimated. The size of the fertilizer particles formed by the granulator is not completely consistent, and the sifter can screen out large particles or small particles that do not meet the specifications. This ensures the uniformity of the finished fertilizer particles, which can meet the needs of agricultural production, both in terms of appearance and use effect. Uniform fertilizer particles can more accurately control the amount of fertilizer applied during the application process, improve the utilization efficiency of fertilizer and reduce waste. In short, the sifter has a profound impact on the quality of fertilizer in many links of fertilizer production, and is one of the key equipment to ensure the high-quality production of fertilizer.