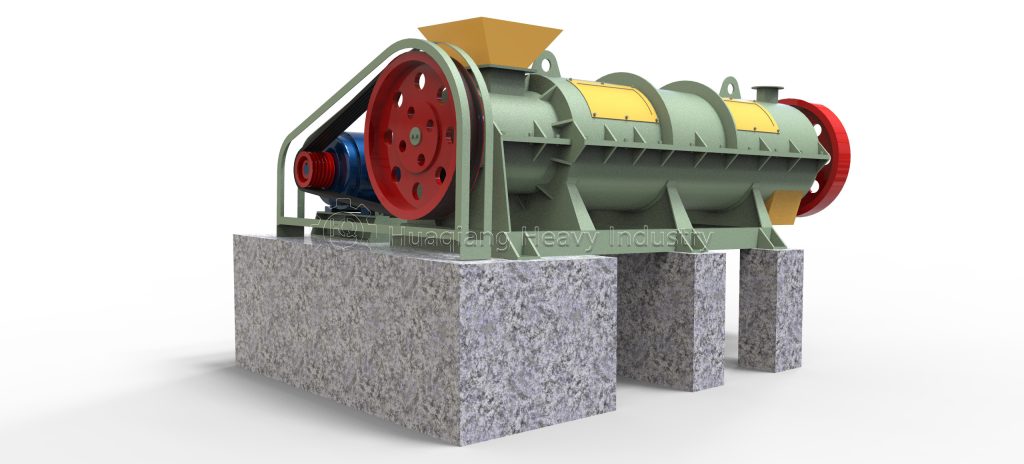

Tooth Granulator: Core Equipment for Efficient Fertilizer Production

The tooth granulator is a mechanical device that extrudes materials into granules through high-speed rotating teeth, widely used in organic fertilizer, compound fertilizer and other fertilizer production fields, with significant advantages such as high granulation efficiency and good particle uniformity.

Working Principle

The tooth granulator completes the granulation process through three main steps:

- Material Mixing: Thoroughly mix raw materials with binder

- Extrusion Forming: High-speed rotating teeth extrude and shear materials

- Particle Shaping: Form uniform granules through screen

Key Advantages

| Advantage | Performance |

| High Efficiency | Capacity up to 5-20 tons/hour |

| Uniform Particles | Particle roundness over 90% |

| Strong Adaptability | Can process various material combinations |

| Low Energy Consumption | 30-40% energy saving compared to traditional methods |

Selection Guide

- Choose appropriate modelbased on capacity needs (Small:5-10t/h, Medium:10-15t/h, Large:15-20t/h)

- Consider material characteristics: Match equipment performance with moisture content, viscosity etc.

- Focus on key components: Tooth material (wear-resistant alloy steel recommended), motor power

- Automation level: Modern equipment should have PLC control system

References:

- International Fertilizer Equipment Association “Granulation Technology Guide” (2023)

- Wang et al. “Advanced granulation technologies in fertilizer production” (2022)