What fertilizer equipment does the organic fertilizer production line have?

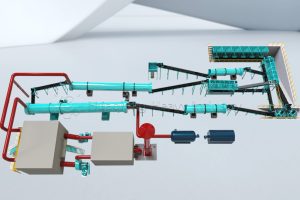

The whole set of organic fertilizer production line mainly includes the following fertilizer equipment:

Fermentation system equipment: including fermentation turning machine, its main function is to turn the raw materials during the fermentation process, provide sufficient oxygen and control the temperature, so that the raw materials can be fermented more evenly and fully.

Crushing equipment: such as semi-wet material crusher, used to finely crush the fermented materials to make them uniform in size.

Mixing equipment: such as horizontal mixer, used to mix and mix a variety of raw materials.

Granulating equipment: such as stirring tooth granulator or organic fertilizer special granulator, used to make the mixed materials into organic fertilizer particles of uniform size, which is convenient for sorting and packaging.

Drying and cooling equipment: including drum dryer and cooler. The dryer is used to dry the granular materials with moisture, while the cooler quickly cools the dried materials to increase production efficiency.

Screening equipment: such as drum screening machine, used to screen and grade the finished fertilizer, screen out unqualified particles, and qualified particles flow into the next link.

Packaging equipment: including automatic packaging machines or automatic weighing packaging machines, which are used to quantitatively bag and package the finished organic fertilizer particles.

In addition, depending on the degree of automation and production scale of the organic fertilizer production line, there may be other auxiliary equipment, such as belt conveyors, coating machines, etc. The function of the coating machine is to coat the outside of the finished particles to effectively prevent the fertilizer from agglomerating.

Please note that although the process structure is roughly the same, the configured fertilizer equipment is not fixed. Huaqiang Heavy Industry will design and provide customers with organic fertilizer production line construction and equipment selection plans that meet their own conditions based on the user’s material characteristics, on-site working conditions, specific production requirements, degree of automation, and investment budget.