Why has the flat die granulator become such a versatile tool in the fertilizer industry?

When raw materials of varying textures face granulation challenges, who can shoulder the heavy responsibility? The flat die granulator offers the answer with its strength—and when paired with a well-matched partner, it’s the ultimate in fertilizer production!

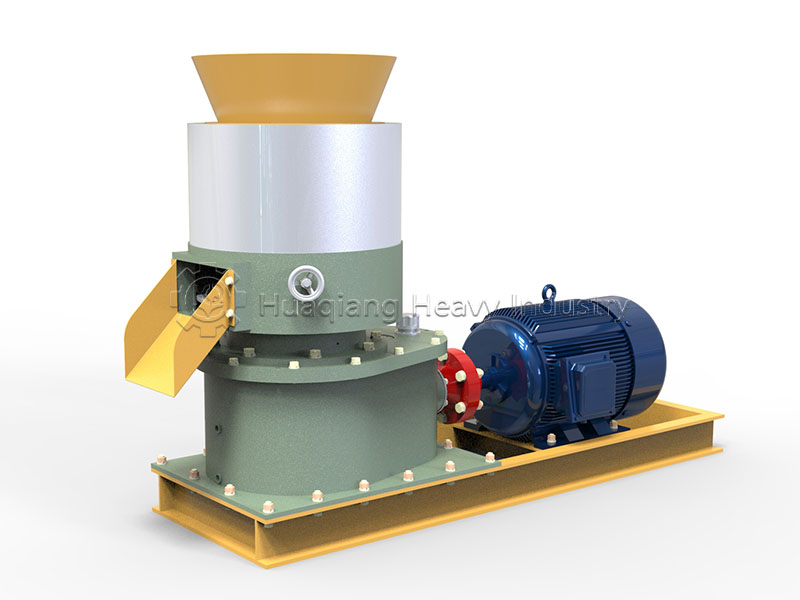

The flat die granulator’s most impressive feature is its “iron frame” and “flexible mind.” The steel plate flat die is densely packed with neatly arranged holes. The pressing wheel, like a tireless craftsman, steadily presses the raw material into the holes, producing pellets as uniform in length as if measured with a ruler. Whether it’s coarse-fiber straw or sticky livestock manure, it can handle it with ease, requiring no complex adjustments.Frequent material changes are no problem; this ability to “accept all” allows even small-batch production to be handled with ease.

But the real work is never a one-person show. The chain crusher first grinds the bulky raw materials into a fine powder, like meticulously chopping the ingredients. The vertical disc mixer, like a seasoning master, blends elements like nitrogen, phosphorus, and potassium to a harmonious blend. The dryer gives the freshly baked pellets a “sunbath” to achieve just the right moisture content. The cooler then adds a gentle breeze, instantly achieving the desired hardness. These devices are like precisely meshed gears; without any one, nothing would work smoothly.

From fluffy raw materials to solid pellets, the flat die pelletizer and its partners perform magical transformations. It doesn’t prioritize speed, but rather earns trust through stability and reliability. It doesn’t demand fancy features, but can easily meet diverse needs. Isn’t this “pragmatic” approach the perfect companion for small and medium-sized fertilizer plants?