Customized Solutions for Pig Manure Organic Fertilizer Production Lines: Achieving a Double Harvest of Environmental Protection and Economic Benefits

Raw Material Characteristics and Processing Challenges

Pig manure, a common organic waste in traditional agricultural production, boasts advantages such as rich nitrogen, phosphorus, and potassium content and high organic matter content, making it an ideal raw material for producing high-quality organic fertilizer. However, fresh pig manure has a high moisture content of 70%-85%, is highly sticky, and has a strong odor. These characteristics pose significant challenges to large-scale processing and resource utilization. How to transform this high-moisture, high-viscosity raw material into stable and efficient commercial organic fertilizer has become an important issue for modern livestock enterprises and organic fertilizer producers.

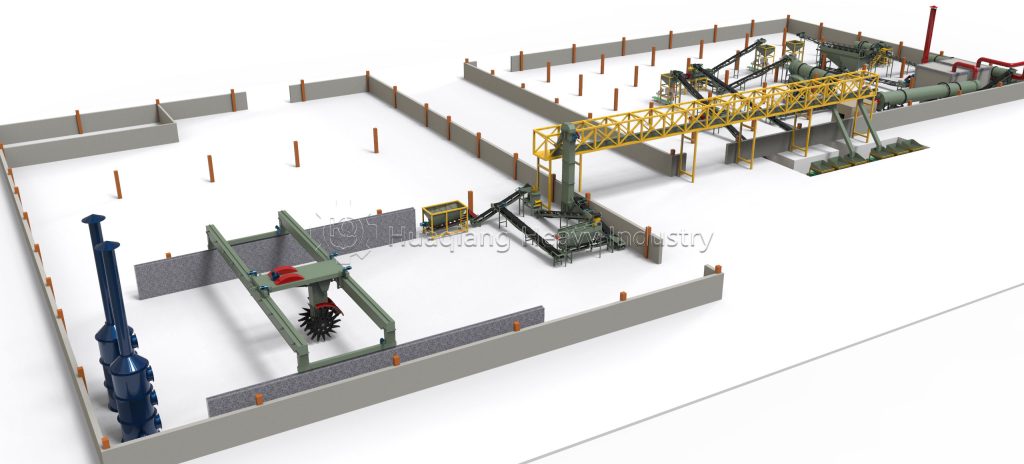

Pretreatment System: Solving the High Moisture, High-Viscosity Problem

Pretreatment is the first step in pig manure organic fertilizer production, directly determining the smooth progress of subsequent processes. To address the problem of excessively high moisture content in pig manure, the production line is first equipped with powerful solid-liquid separation equipment. Through mechanical extrusion, the moisture content is rapidly reduced to below 55%, creating suitable conditions for subsequent processing. The separated solid material then enters a specially designed semi-wet material crusher. This equipment employs a special toothed structure and high-strength alloy blades to effectively overcome the stickiness of pig manure, achieving efficient, non-sticky crushing and improving the material fineness to over 80 mesh.

This stage of process optimization not only solves the raw material handling problem but also lays a solid foundation for subsequent fermentation through precise moisture control. A specially designed anti-clogging system and automated control device ensure continuous and stable operation of the pretreatment stage, with a processing capacity of over 5 tons per hour, meeting the needs of large-scale production.

Fermentation Process: Achieving Harmlessness and Stabilization

Fermentation is the core step in pig manure organic fertilizer production, directly affecting the product’s safety and fertilizer efficiency. The production line uses advanced dynamic fermentation technology, and depending on site conditions, a hydraulic turner or a trough fermentation system can be selected. During fermentation, a special compound microbial agent is added to precisely adjust the carbon-to-nitrogen ratio of the material to the ideal range of 25:1-30:1, creating the most suitable environment for microbial reproduction.

The entire fermentation process is meticulously controlled, with the temperature strictly maintained within a high-temperature range of 55-65℃ for 10-15 days. This high-temperature fermentation process effectively kills pathogenic microorganisms and insect eggs, eliminates antibiotic residues, and promotes the full decomposition of organic matter. Regular operation of the turning equipment ensures uniform heating and sufficient aeration of the material, significantly shortening the fermentation cycle and improving the quality of decomposition.

Forming and Post-processing: Creating High-Quality Commercial Fertilizer

The fermented material enters the forming and processing stage. Considering the characteristics of pig manure organic fertilizer, a two-in-one granulation device is recommended. This equipment can directly form uniform granules from fermented material without drying pretreatment, achieving a pelleting rate of over 85%, and producing high-strength, non-breakable granules. For large-scale production enterprises, a drum drying and cooling system can be added to control the final moisture content of the granules below 10%, significantly extending the product’s shelf life.

Post-processing steps include grading and screening, and automatic packaging. Multi-layer vibrating screens accurately grade the finished product according to particle size; unqualified granules are returned for reprocessing, ensuring uniform product specifications. The fully automatic packaging system achieves quantitative weighing, automatic bagging, and sealing, with a packaging efficiency of 800-1000 bags per hour, significantly improving the automation level of the production line.

Economic Benefits and Environmental Value: The return on investment for pig manure organic fertilizer production lines is significant. Taking a 3-ton/hour production line designed by Huaqiang Heavy Industry for a 10,000-head pig farm as an example, this system processes 30 tons of pig manure daily, with an annual output of 18,000 tons. Based on the current market price of 800 yuan per ton, annual sales revenue could reach 14.4 million yuan. While solving the problem of manure treatment in livestock farms, it also creates considerable economic benefits.

More importantly, this solution achieves resource utilization of waste, reducing environmental pollution pressure and aligning with current policies promoting green development and a circular economy. The production line’s closed design and exhaust gas treatment system effectively control odor diffusion and dust emissions during production, achieving clean production.

Technological Innovation and Continuous Improvement: With technological advancements and changing market demands, pig manure organic fertilizer production lines are developing towards greater intelligence and efficiency. The application of new biological deodorization technology, intelligent temperature control systems, and remote monitoring platforms makes the production line more stable and reliable. Simultaneously, customized designs for different regional climate conditions and raw material characteristics ensure the adaptability and practicality of the solution in various environments.

Through scientific and reasonable process design and professional and reliable equipment configuration, the pig manure organic fertilizer production line not only solves the environmental pressure of the livestock industry, but also creates new economic growth points, achieving a perfect unity of economic and environmental benefits, and providing a practical solution for sustainable agricultural development.

Granulation Technology for High-Moisture Organic Feedstocks

Following the intensive fermentation phase, often accelerated by a large wheel compost turning machine or a chain compost turning machine, the cured pig manure compost is ready for the final shaping process within a complete organic fertilizer production line. The stage of organic fertilizer production granulation offers multiple technology paths to accommodate the material’s characteristics. A traditional and effective method is the organic fertilizer disc granulation production line, which utilizes an organic fertilizer disc granulation machine to form spherical pellets via a tumbling action.

For operations seeking efficiency, a new type two in one organic fertilizer granulator that combines mixing and granulation can be advantageous. For producing dense, cylindrical pellets, a flat die press pellet machine for sale offers a robust extrusion solution. More complex systems, like an organic fertilizer combined granulation production line, may integrate different granulators. Alternatively, a double roller press granulator can be used for dry compaction if the moisture content is sufficiently reduced. The selection of the appropriate granulation technology is a critical decision in organic fertilizer manufacturing, directly impacting the final product’s physical properties, production cost, and marketability.

This integrated approach—from dewatering and composting to flexible granulation—demonstrates how challenging waste streams like pig manure can be systematically transformed into a standardized, value-added agricultural product, closing the nutrient loop on the farm.