Compost Turning Machine Showdown: Chain vs Wheel

The choice between chain and wheel compost turners significantly impacts the organic fertilizer production process. These machines accelerate decomposition by aerating organic materials, with chain types excelling in deep-turning large windrows while wheel models offer better maneuverability for smaller operations, both crucial for efficient compost maturation in fertilizer production lines.

The Heavyweight Champion: Chain Compost Turning Machine

Built like an industrial tank, chain compost turning machine dominate large-scale operations with their brute strength. Multiple rotating chains fitted with sturdy paddles churn through compost piles like a giant comb, achieving unparalleled mixing depth. Their secret weapon? The ability to handle dense, fibrous materials that would stall other machines. Perfect for municipal waste facilities and large farms, these beasts can process windrows up to 3 meters high while maintaining consistent aeration throughout the pile.

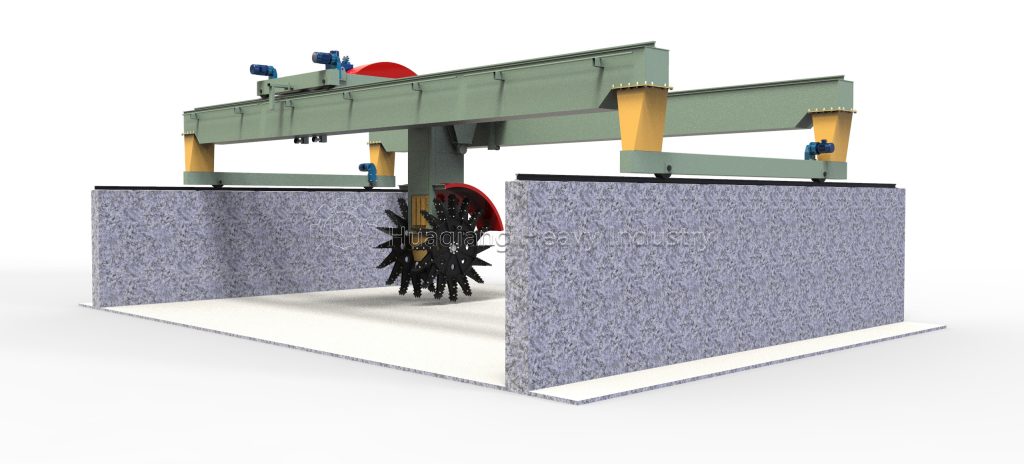

The Agile Performer: Large Wheel Turner

Imagine a massive rolling pin aerating your compost – that’s the wheel turner in action. Its signature oversized wheels (some reaching 2 meters in diameter) gently lift and tumble material as they roll. This design excels at preserving delicate microbial communities while preventing compaction. The wheels’ smooth rotation requires less power than chain systems, making them the energy-efficient choice for organic farms and mid-sized operations processing 100-500 tons daily.

Choosing Your Champion

Chain Turners shine when: Processing tough materials (yard waste, municipal compost), working in large facilities (>5 acres), or handling high-volume production (>500 tons/day).

Wheel Turners win when: Handling delicate compost mixes (food waste, manure blends), operating in confined spaces, or prioritizing energy efficiency over raw power.

Pro Tips for Peak Performance

Regardless of your choice, smart operation doubles your machine’s effectiveness. For chain systems, maintain consistent speed – too fast causes uneven turning, too slow reduces output. Wheel turners perform best with properly sized windrows (1.5-2m height) and regular moisture monitoring. Both types benefit from scheduled maintenance: grease those bearings monthly and inspect wear parts quarterly. Remember, the perfect turning frequency depends on your material – most operations find 2-3 turns weekly achieves ideal decomposition.

In the composting arena, there’s no universal “best” machine – only the best machine for your specific needs. By matching equipment to your materials and scale, you’ll transform organic waste into black gold with maximum efficiency.