Fertilizer Granulator: The Miracle at the Heart of the NPK Production Line?

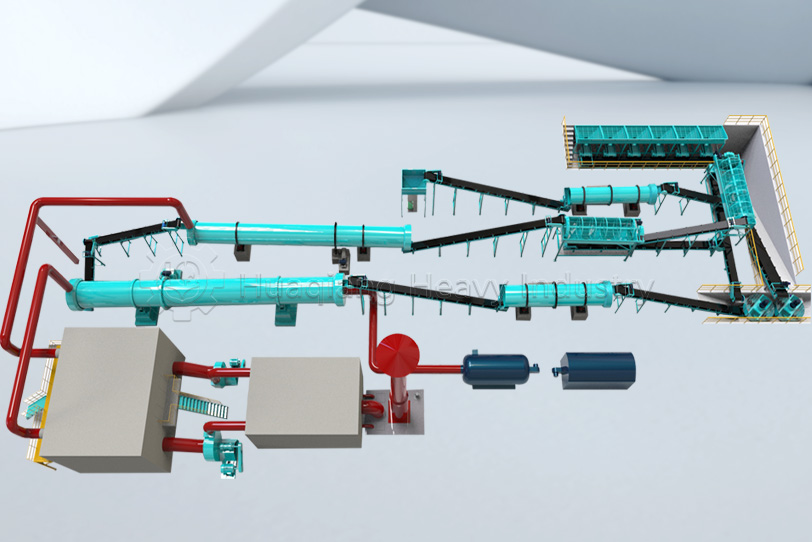

In the complex arena of modern fertilizer production, the NPK production line is like a meticulously orchestrated symphony, with every piece of equipment playing an essential role. After being broken down by the fertilizer crusher, the raw materials flow through a conveying system into the mixer, where nutrients like nitrogen, phosphorus, and potassium are meticulously blended like paint on a palette. However, what truly brings this production symphony to its climax is the magical transformation of the fertilizer granulator—transforming the evenly mixed powder into perfectly granulated particles.

The fertilizer granulator is the heart of the NPK production line. It not only determines the physical form of the final product but also directly impacts fertilizer application effectiveness. Through a unique rotation or extrusion process, these machines precisely control granule size, hardness, and density, ensuring a slow release of nutrients into the soil and significantly improving fertilizer utilization. Furthermore, the accompanying dryer and cooler provide the final quality assurance for the granules, ensuring their stability and durability.

From raw material processing to finished product packaging, the various equipment on the NPK production line works together to create an efficient and environmentally friendly production system. The fertilizer granulator, at the heart of this system, is not only a culmination of engineering expertise but also a vital bridge connecting science and agriculture, the laboratory and the field. At a time when global food security faces challenges, these seemingly ordinary machines are quietly nourishing our shared home, the Earth, in extraordinary ways.