NPK Fertilizer Production Line: How to Create a Comprehensive Nutrient Supply?

Modern agriculture demands precise fertilizer delivery. NPK fertilizers, which simultaneously provide the three core nutrients nitrogen (N), phosphorus (P), and potassium (K), have become a “nutritional treasure trove” for high crop yields. A mature NPK fertilizer production line is a “magic factory” that transforms multiple raw materials into highly effective compound fertilizers. Through the coordinated operation of multiple devices, it enables more scientific nutrient combinations and a more efficient production process.

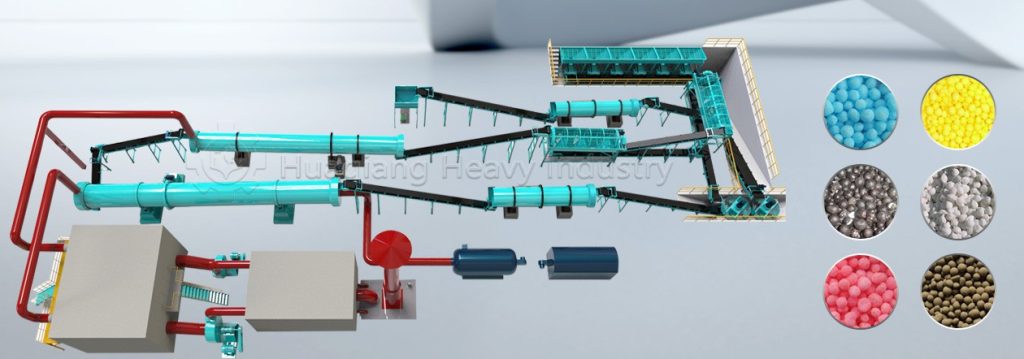

The NPK fertilizer production line has a tightly linked process, starting with raw material pretreatment. Basic raw materials such as urea, monoammonium phosphate, and potassium chloride are first crushed into fine particles in a crusher. Then, they are screened through a vibrating screen to remove impurities and lumps, ensuring uniform particle size. This step, like “preparing ingredients” before cooking, lays the foundation for subsequent mixing. Next, the precision batching system enters the picture. Like an intelligent chef, it uses an electronic scale to precisely adjust the proportions of nitrogen, phosphorus, potassium, and trace elements based on the nutrient requirements of different crops (such as rice, wheat, and fruits and vegetables). The accuracy can be controlled to within 0.5%, ensuring that each batch of fertilizer meets the standard nutrient ratio.

The mixing stage is the “heart of the kitchen” of the production line. A dual-shaft, zero-gravity mixer, with its high-speed rotating blades, thoroughly tumbles and blends the various raw materials within a confined space. This achieves uniform mixing in just minutes, preventing nutrient stratification. The mixed materials then enter the granulation stage. Currently, mainstream extrusion granulators or rotary drum granulators press or roll the mixture into granules with a diameter of 2-4 mm. These granules are not only easy to transport and apply, but also slow the release of nutrients.

After granulation, the granules pass through a rotary fertilizer dryer to remove moisture and then enter a cooler for rapid cooling to prevent clumping and deterioration.

The finished product screen then screens the pellets again, sending unqualified pellets back to the crusher for reprocessing. Qualified pellets enter the automated packaging system, where they are packaged into standard 25 kg or 50 kg bags. Finally, they are transported to the finished product warehouse via a conveyor belt. Throughout this process, a central control system monitors parameters such as temperature, speed, and output of each device in real time, achieving full automation. This reduces manual intervention and ensures consistent product quality.

From raw materials to finished product, the NPK fertilizer production line meets the individual nutrient needs of different crops with precision and efficiency.