Bio-Organic Fertilizer Equipment: Adapting to Sustainable Agricultural Development

Against the backdrop of the global agricultural shift towards green, circular, and low-carbon practices, bio-organic fertilizer is rapidly emerging from an alternative fertilizer to a core strategic resource for ensuring food security and restoring arable land ecosystems. The key support for this industry’s rise is modern “bio-organic fertilizer equipment” capable of transforming agricultural waste into valuable resources.

Market Logic: From “Waste Treatment” to “Soil Health Investment”

The growth of the bio-organic fertilizer market follows a clear “dual value” logic. On the one hand, it is a necessary solution to environmental pressure. Large-scale livestock farming and concentrated production generate vast amounts of organic waste such as animal manure and crop residues, and traditional methods of piling or direct discharge have become significant sources of non-point source pollution. Standardized treatment and resource utilization of this waste is a rigid requirement for sustainable agricultural development. On the other hand, it is an urgent remedy for soil degradation. Long-term overuse of chemical fertilizers has led to soil compaction, decreased organic matter, and microbial community imbalance, seriously threatening the sustainability of arable land quality and productivity. Bio-organic fertilizer combines “organic matter” to improve soil and “functional microorganisms” to activate nutrients, making it one of the most effective means of systematically addressing soil sub-health, improving crop resistance, and enhancing the flavor of agricultural products.

Therefore, investing in bio-organic fertilizer production is not only an act of environmental compliance but also a long-term investment in the health of arable land, the most important agricultural production resource. Its market potential is directly linked to the nation’s commitment to soil protection and the growing consumer demand for high-quality agricultural products.

Core Equipment: Building the Conversion Hub from “Waste” to “Resource”

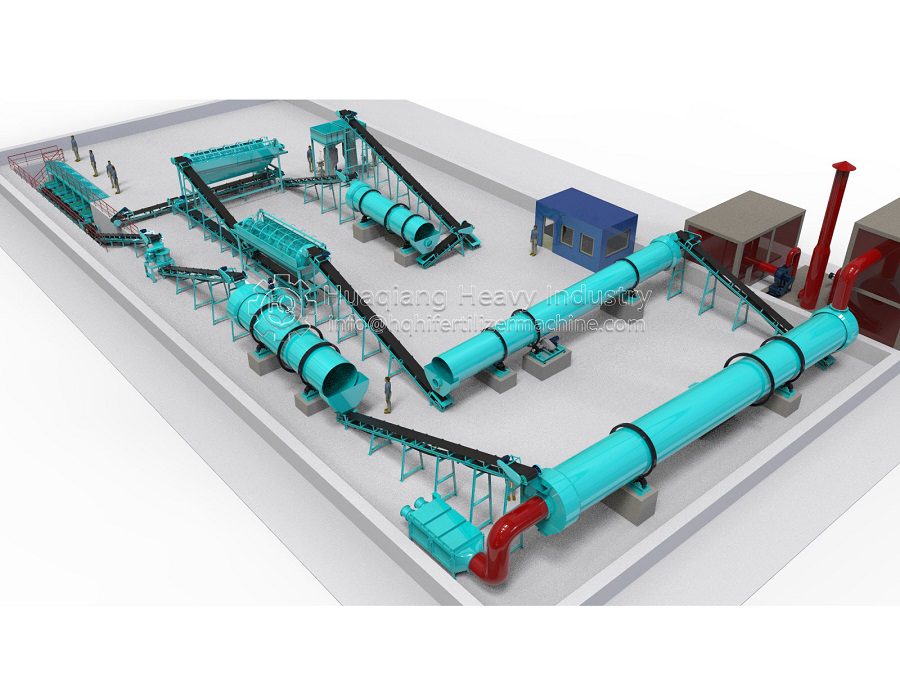

A complete and efficient bio-organic fertilizer production line hinges on two key conversion stages, each completed by two types of critical equipment.

First Stage: High-Efficiency, Stable Fermentation and Composting System

This is the foundation for transforming unstable organic waste, potentially carrying pests and diseases, into safe, stable “humus.” Traditional open-air composting is inefficient, time-consuming, and poses high environmental risks, making it unsuitable for industrial production. Modern processes primarily rely on two core types of equipment: For projects with high output and standardization requirements, intelligent high-temperature aerobic fermentation tanks are the preferred choice. Through sealed tanks, forced ventilation, and stirring, the material can be thoroughly composted within 10-15 days, killing harmful organisms. The process is odorless and highly efficient. For projects with large processing volumes and loose raw materials, the trough-type composting system offers an excellent balance between cost and efficiency. Regardless of the form, the goal is the same: to create a stable and safe “home” for the subsequently added functional microorganisms.

Second stage: Precise and active microbial addition process

This is the soul of giving the product its “biological” functionality. Simple physical mixing cannot guarantee the survival and uniformity of microorganisms. A professional microbial mixing and coating system requires that high-concentration liquid or solid microbial agents be uniformly adsorbed onto the cooled, composted organic carrier in a clean environment through precise metering and low-temperature, gentle mixing processes. Key equipment includes sterile inoculation devices and low-temperature twin-shaft mixers. The core design principle is to minimize mechanical and thermal damage to the functional microorganisms, ensuring that the product contains sufficient quantities of highly active effective bacterial colonies upon leaving the factory.

Profound Value: Productivity Beyond Fertilizer Itself

Investing in advanced “bio-organic fertilizer equipment” has far-reaching significance that goes beyond simply producing qualified products. The rise of the bio-organic fertilizer industry is a systemic answer to the demands of sustainable agricultural development in our time. Professional and efficient “bio-organic fertilizer equipment” is the key to writing this answer. It is not only a commercial choice that follows the trend, but also a strategic investment in restoring the earth’s ecosystem, building a future agricultural system, and creating a more sustainable future. Investing in this is investing in more fertile soil, a more resilient agriculture, and a more sustainable future.

Following the fermentation and microbial inoculation stages, the next critical phase in the bio organic fertilizer production line is organic fertilizer production granulation. This step transforms the inoculated compost into a uniform, marketable, and easy-to-apply physical form. The equipments required for biofertilizer production for this stage offer several options. For operations seeking a compact solution, a new type two in one organic fertilizer granulator that combines crushing and shaping can be highly efficient. Alternatively, a dedicated flat die pelleting machine is an excellent choice for producing high-density, cylindrical organic pellets, particularly suitable for small to medium-scale production. The selection of the appropriate granulation technology is crucial for ensuring the physical quality of the final product, preserving microbial viability, and meeting specific application requirements, thereby completing the value chain from raw waste to a sophisticated soil amendment.