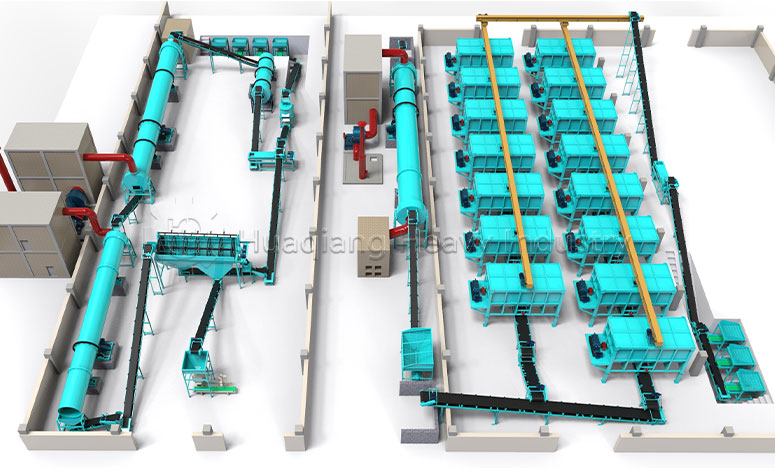

Bio-Organic Fertilizer Production Line: An Intelligent Ecosystem Transforming Waste into Wealth

A modern bio-organic fertilizer production line is far more than a collection of machines; it is a carefully orchestrated, intelligent ecosystem that synergistically combines mechanical processing, controlled biology, and digital intelligence. It transforms diverse organic wastes—from agricultural residues and livestock manure to municipal green waste—into a potent, living soil amendment teeming with beneficial microorganisms. This journey from raw, often problematic waste to a standardized, high-value product is a marvel of applied engineering and biological science.

The Production Symphony: A Four-Act Process

The transformation occurs through four seamlessly integrated stages, each critical to ensuring the final product’s efficacy, safety, and quality.

Act 1: Raw Material Reception & Intelligent Pre-processing

The line begins at the loader feeding hopper, the gateway where heterogeneous raw materials are received. Here, high-moisture, sticky materials like fresh manure are shattered in a half-wet material crusher, designed specifically to pulverize without clogging. Fibrous materials like straw are processed separately in a dedicated straw crusher. These size-reduced components are then precisely metered by a uniform feeder into a double shaft mixer. In this mixer, the organic base is thoroughly blended with specific, carefully selected strains of beneficial microbial inoculants (bacteria, fungi, actinomycetes) and mineral amendments, creating the perfect “seedbed” for fermentation.

Act 2: Controlled Aerobic Fermentation – The Heart of the Process

This is where biology takes the lead, facilitated by precision engineering. The prepared mix is conveyed into long, concrete fermentation troughs. A double screws compost turner (or a hydraulic trough compost turner) moves on rails, periodically traversing the troughs. Its action is vital: it aerates the pile, regulates temperature and moisture, and ensures homogeneous conditions. This controlled environment allows the inoculated microbes to thrive, rapidly decomposing organic matter, generating heat to eliminate pathogens, and synthesizing stable humus and bioactive compounds. Advanced lines integrate real-time sensor networks (temperature, oxygen, moisture) that feed data to a central PLC, allowing the turner’s operation to be optimized automatically for the fastest, most consistent bio-conversion.

Act 3: Refinement & Value-Added Formulation

Post-fermentation, the matured and stabilized compost may be cured before refinement. It is then screened by a rotary screener to achieve a uniform texture. For premium products, the material enters a rotary drum granulator or a new type two-in-one organic fertilizer granulator. The latter is highly efficient for semi-wet materials, combining crushing and granulation in one step. The resulting “green” pellets are then gently dried and cooled in a rotary dryer and cooler to preserve microbial viability while achieving physical stability. A final screening step ensures perfect granule size.

Act 4: Packaging, Preservation & Dispatch

The finished bio-organic fertilizer, now a granular or powdered product rich in organic matter and living microbes, is elevated to storage silos by equipment like a large angle belt conveyor. An automatic quantitative packaging system doses the product into bags, which are sealed to preserve moisture content and microbial life. The entire packaging area is often environmentally controlled to protect the delicate biological component of the product.

Core Technological Pillars of a Modern Line

Modular & Scalable Design: Lines can be configured from pilot scale to fully industrial, continuous-feed systems exceeding 100,000 tons annual output.

Digitization & IoT Integration: The “Smart Farm” concept extends to production. Every critical parameter—from crusher load to fermentation temperature—is monitored and logged, enabling traceability, predictive maintenance, and recipe management via a central SCADA system.

Closed-Loop Environmental Control: Negative-pressure systems with biofilters or chemical scrubbers contain dust and odors at every stage. Process water is often recycled. This turns an organics processing facility into a good neighbor, operating with minimal environmental footprint.

Focus on Microbial Vitality: Unlike simple composting, every step—from moderate-temperature drying to gentle conveying—is designed to protect and enhance the viability of the added microbial consortia, which are the defining feature and value-driver of true bio-organic fertilizer.

Conclusion: More Than Fertilizer, A Soil Health Solution

A state-of-the-art bio-organic fertilizer production line is a testament to sustainable technology. It solves pressing waste disposal issues while manufacturing a product that rejuvenates degraded soils, improves crop resilience, and reduces dependence on chemical inputs. By marrying robust mechanical handling with precise biological management, this intelligent ecosystem doesn’t just produce fertilizer; it produces the foundation for the next generation of regenerative agriculture.