Bio-Organic Fertilizer Production Line: The Art of Transforming Waste into Black Gold

In today’s pursuit of sustainable agriculture, the bio-organic fertilizer production line is emerging as the core hub connecting organic waste treatment with ecological farming. This is more than just a production line; it is a systematic eco-engineering technology that transforms waste into high-value fertilizer.

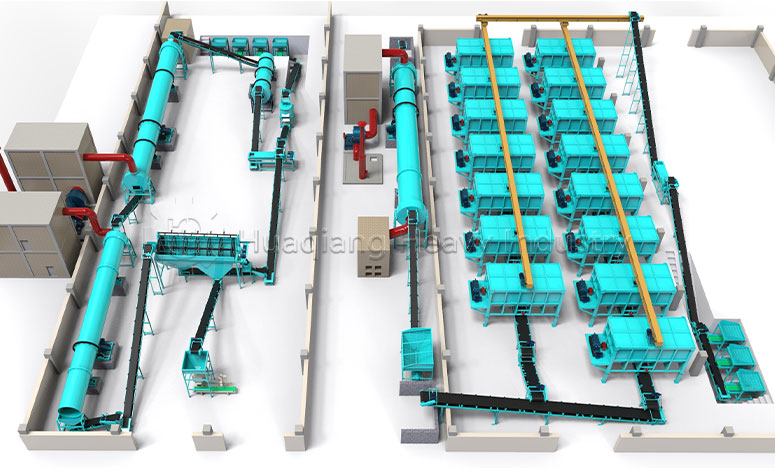

The Core Process Flow

Stage 1: Raw Material Pretreatment & Formulation

This is the starting point for quality. Various raw materials are first homogenized by a half-wet material crusher. Subsequently, materials and core functional microbial inoculants are thoroughly mixed in a Double Shaft Mixer to create optimal fermentation conditions.

Stage 2: Aerobic Fermentation & Maturation

This is the “heart” of the line. The mixed material is fermented. Depending on scale, one can choose windrow composting using a Windrow Composting Machine or in-vessel composting using a Chain Compost Turner. Microorganisms decompose organics, generating heat to kill pathogens over 15-30 days.

Stage 3: Refining, Shaping & Finishing

The matured material is refined using a cage crusher, then shaped into granules by a flat die pelleting machine or disc granulator. Granules are dried in a rotary drum fertilizer dryer, cooled, and may be coated before automatic packaging.

Core Philosophy: Flexibility, Efficiency, Intelligence

The line features modular design for flexible configuration. Intelligent control systems enable data-driven production, while integrated environmental systems ensure a clean operation from waste to resource.

Beyond Fertilizer: Multiple Values Created

This investment creates layered value: Environmental value by solving waste pollution; Agricultural value by improving soil health and crop resilience; Economic value by transforming waste into a profitable product.

A well-designed bio-organic fertilizer production line is a mobile resource conversion factory. It marks the transition to a new industrial era of standardization, scale, and intelligence in organic fertilizer production. For enterprises in green agriculture, this is a far-sighted investment and a tangible action for planetary health.

Why Choose a Modern Bio-Organic Fertilizer Production Line?

Scientific Production: A Leap in Quality & Efficiency

Through precise process control, the production line condenses months of natural composting into a controllable 20-30 day cycle. Intelligent systems regulate temperature and humidity, ensuring every batch is highly matured, harmless, and rich in active microbes, with quality consistency far surpassing traditional compost.

Revolutionary Resource Conversion Efficiency

Capable of processing hundreds of tons daily, it systematically solves concentrated organic waste problems. It acts as a highly efficient “waste converter”, transforming environmental burdens into economic assets and realizing a genuine circular economy.

Multiplied Product Value & Market Competitiveness

By adding functional microbial strains, the product is upgraded from basic organic fertilizer to a bio-agent fertilizer with defined benefits (disease resistance, growth promotion, etc.). This significantly enhances its value and profit margin in the premium agricultural market.

Environmental Benefits & Social Responsibility

With closed designs and bio-filtration systems, production has near-zero secondary pollution. Its large-scale use reduces chemical runoff, improves soil organic matter, and sequesters carbon—making it a practical solution for climate change and agricultural carbon neutrality.