How Can Tiny Pellets Nourish the World? Exploring the NPK Fertilizer Production Line!

In modern agriculture, the NPK fertilizer production line plays a crucial role in ensuring global food security through its precise design and efficient operation. This complete production line transforms raw materials into nutritionally balanced fertilizer pellets, with each step showcasing exquisite engineering and wisdom.

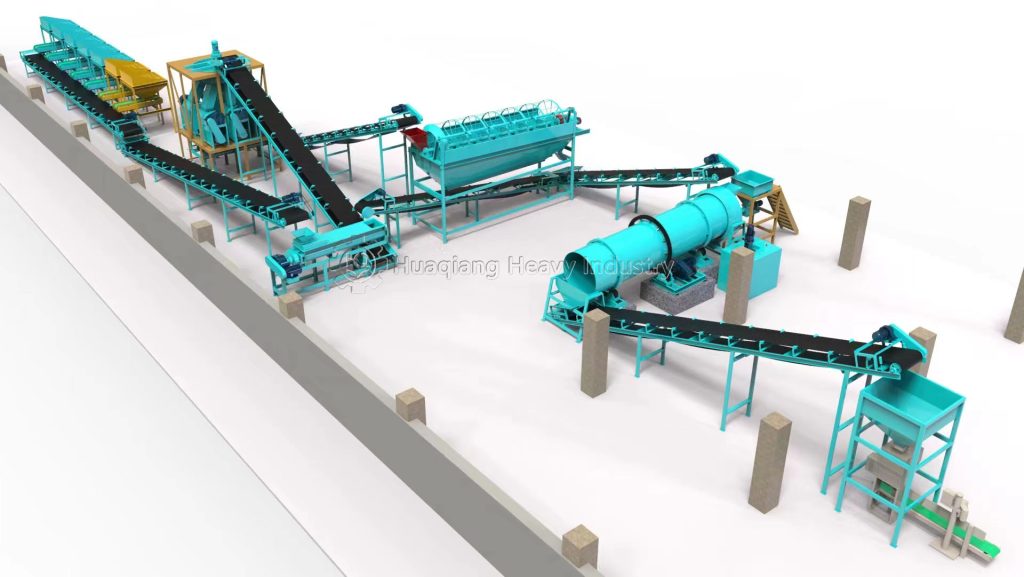

The entire NPK manufacturing process begins with raw material processing. Crushers and batching machines work together to pulverize materials and accurately measure proportions, ensuring the perfect balance of nitrogen, phosphorus, potassium, and other elements. Subsequently, double-shaft paddle mixers or V-shaped mixers thoroughly blend these materials, laying the foundation for subsequent granulation.

The granulation stage represents the core of the NPK production process. The NPK fertilizer granulator machine forms uniform pellets from the mixed materials, with disc granulators, drum granulators, or extrusion granulators all prioritizing pellet quality as their primary objective.

The subsequent drying and cooling processes are equally vital. Fluidized bed dryers or rotary drum dryers remove moisture from the pellets, while cooling drums reduce the temperature to suitable levels. Screening equipment further eliminates unqualified particles, ensuring consistent product size.

To enhance fertilizer performance, optional coating equipment applies a protective film on the pellet surface, improving moisture resistance and controlling nutrient release rates. Finally, automatic packaging machines complete weighing and packaging, while PLC control systems monitor the entire process to ensure efficient and stable production line operation.

This intelligent production line not only improves fertilizer quality but also promotes sustainable agricultural development.