How to transform waste into black gold? The secrets of organic fertilizer production revealed!

Amid the wave of sustainable agriculture, organic fertilizer production process is quietly undergoing a revolution. It’s no longer simply composting; it’s a sophisticated art that blends traditional wisdom with modern technology, transforming agricultural waste into “black gold” that nourishes the soil.

Raw Material Pretreatment: The Beginning of Careful Preparation

The journey to high-quality organic fertilizer begins with the meticulous selection and preparation of raw materials. Organic waste, such as livestock and poultry manure, crop straw, and food processing residues, first passes through a crusher to break them down into uniform particles. A magnetic separator then removes metallic impurities, ensuring the purity of the final product and ensuring equipment safety.

Fermentation: A Grand Symphony of Microorganisms

This is the core of the entire process. Pre-treated raw materials are fed into fermentation tanks, where specific strains of bacteria are added and the water and carbon-nitrogen ratios are precisely controlled. With regular agitation in compost turning machine, the microorganisms begin their work—decomposing the organic matter and generating high temperatures to kill pathogens and weed seeds. This process not only reduces the volume but also converts nutrients into a form more easily absorbed by plants.

Synergistic Effects of Supporting Equipment

Modern organic fertilizer production lines no longer operate in isolation. They are often designed in conjunction with chemical fertilizer production equipment to create organic-inorganic compound fertilizer production lines. This integration enables producers to precisely adjust nutrient ratios to meet the specific needs of different crops, maximizing fertilizer effectiveness.

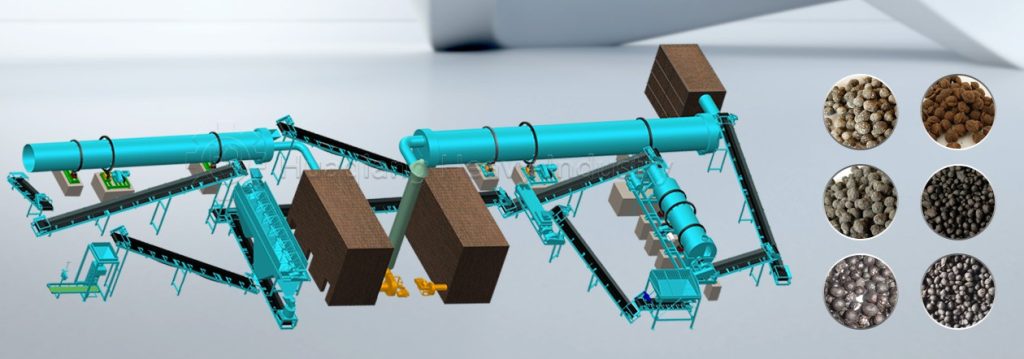

Fine Processing and Forming: Shaping the Perfect Final Product

Fully decomposed material passes through a dryer to reduce moisture, followed by a grinder to a uniform particle size. A fertilizer granulator then converts the powder into uniformly sized granules suitable for application. After a cooler stabilizes the granule temperature, a screening device separates the acceptable product, while oversized or fine granules are returned for further granulation.

Packaging and Storage: The Last Line of Defense for Quality

The final product is weighed and packaged in an automatic packaging machine, typically using moisture-proof materials to preserve fertilizer effectiveness. Proper storage conditions prevent nutrient degradation, ensuring farmers receive the highest quality product.