NPK Fertilizer Production: The Science Behind Perfect Plant Nutrition

How modern technology transforms raw materials into precision-formulated plant nutrition

NPK fertilizer production technology encompasses the scientific methods and technical processes used to create balanced nutrient formulations, while NPK production lines represent the physical implementation of this technology through integrated equipment systems. The relationship is symbiotic: advancements in production technology drive innovations in machinery design, and conversely, improvements in NPK fertilizer production lines enable the practical application of new technological developments. Essentially, the technology provides the know-how for creating optimal fertilizer blends, and the production lines transform this knowledge into tangible products through automated processes including precise batching, mixing, granulation, and packaging.

The Art and Science of NPK Fertilizer Production

Have you ever wondered how farmers achieve those picture-perfect crops with vibrant colors and impressive yields? The secret often lies in NPK fertilizers – precisely formulated plant nutrition containing the essential trio of nitrogen (N), phosphorus (P), and potassium (K). Modern NPK fertilizer production lines represent an engineering marvel, transforming raw materials into uniform, nutrient-rich granules that plants can easily absorb.

From Raw Materials to Nutrient Powerhouses

The journey begins with careful selection and preparation of raw materials. Through an automated, precisely controlled process, these materials undergo transformation into the perfect plant food. The production doesn’t just mix ingredients—it creates specialized formulations tailored to different crops, soil types, and growth stages.

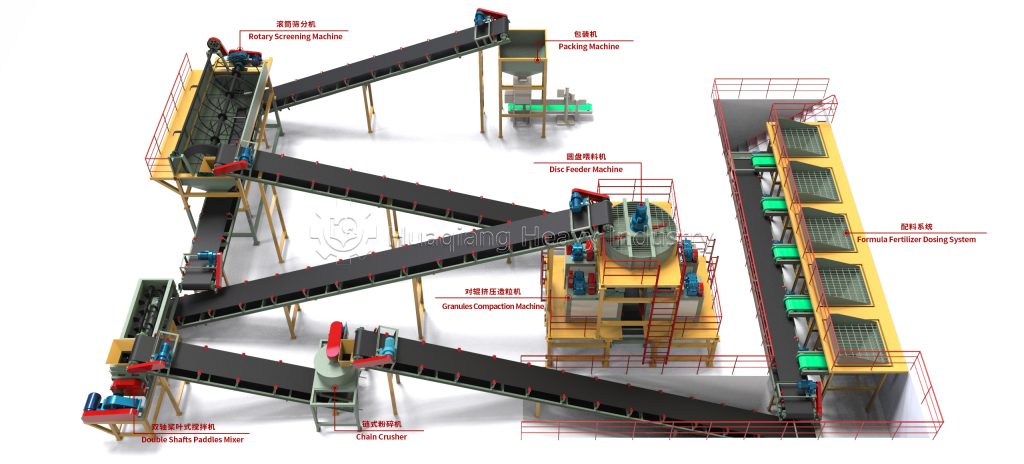

The Precision Equipment Behind Perfect Fertilizer

Raw Material Processing

Crushers and batching systems prepare and measure ingredients with precision, ensuring the perfect NPK ratio in every batch.

Mixing Technology

Advanced mixers like double-shaft blenders or V-shaped mixers create perfectly homogeneous blends for consistent nutrient distribution.

Granulation Magic

Disc, drum, or double roller press granulators transform powdered mixtures into uniform granules ideal for application and absorption.

Drying & Cooling

Fluidized bed dryers and rotary coolers remove moisture and stabilize particles for long shelf life and easy handling.

Quality Control

Screening equipment separates undersized and oversized particles, ensuring consistent product quality in every bag.

Final Touches

Optional coating systems add protective layers, while automated packaging machines prepare the fertilizer for distribution.

The Brain Behind the Operation

What makes modern NPK production truly remarkable is the intelligent control system. PLC-based automation and precision instruments monitor every aspect of the process, ensuring consistent quality, optimal efficiency, and minimal waste. This technological oversight guarantees that each granule contains the promised nutritional value, batch after batch.

More Than Just Fertilizer

NPK production lines don’t just manufacture plant food—they create tailored nutritional solutions that help farmers maximize yields while minimizing environmental impact. By delivering nutrients in precisely formulated ratios, these advanced production systems support sustainable agriculture practices that feed our growing population while protecting our planet.