The Modern Evolution of Organic Fertilizer Production

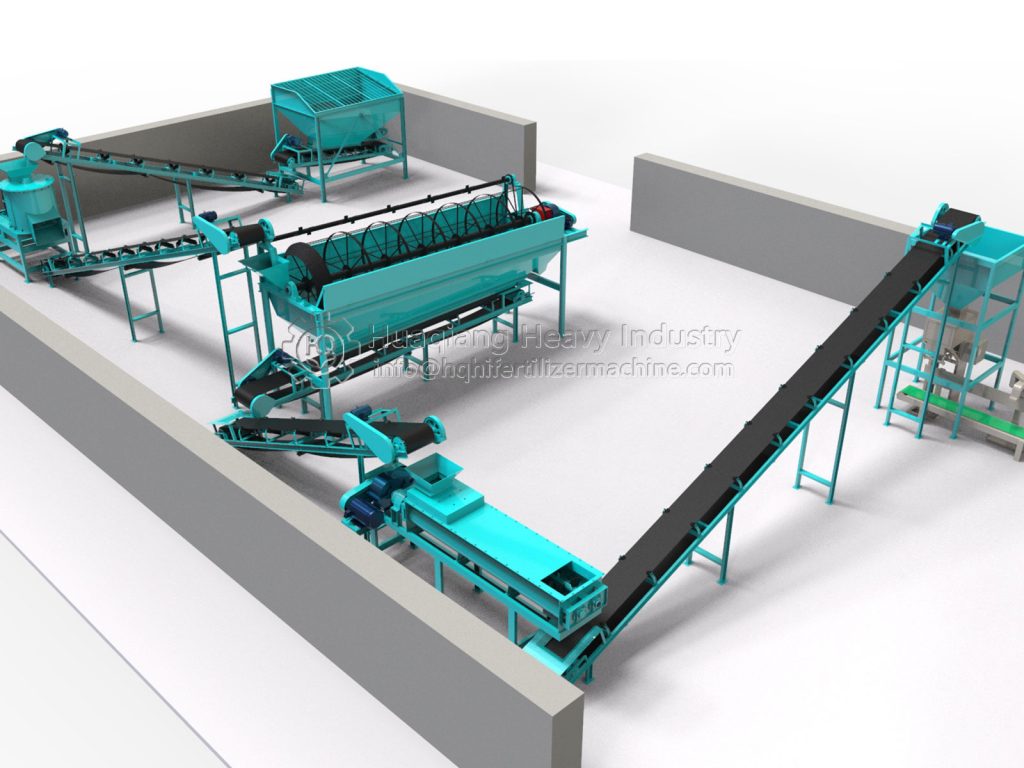

In the wave of sustainable agriculture, organic fertilizer production has transformed from traditional composting methods using equipment like the large wheel compost turner into precisely controlled bioengineering processes. This evolution begins with efficient preprocessing using a wheel compost turner, then progresses through sophisticated granulation systems within a complete organic fertilizer production line.

The transformation is most evident in granulation technology, where various fertilizer granulator options are available. For organic materials, the organic fertilizer granulator and rotary drum granulator excel through gentle drum granulation processes. Meanwhile, for chemical fertilizers, the npk fertilizer granulator plays a crucial role in integrated npk production line setups, often utilizing high-pressure double roller press granulator technology.

Specialized equipment like the double roller granulator and fertilizer roller press machine provide alternative granulation methods, offering flexibility for different material characteristics. This technological evolution not only enhances fertilizer quality but also redefines the value of agricultural waste, creating a sustainable cycle that benefits both agriculture and the environment.

Raw Material Pretreatment: The Foundation of Quality

Modern organic fertilizer production begins with precise raw material formulation. Materials including livestock manure, crop stalks, and food processing by-products undergo strict screening and scientific blending, with carbon-to-nitrogen ratios carefully regulated within the ideal 25-30:1 range. Crushers process materials to optimal particle sizes, creating perfect conditions for subsequent fermentation.

Efficient Fermentation: Precision Control of Microorganisms

Aerobic fermentation stands as the core of the entire process. In modern fermentation tanks, automatically controlled turners regularly aerate the piles, ensuring even oxygen distribution. Temperature sensors continuously monitor pile temperatures, maintaining the golden range of 55-65°C—a temperature that effectively eliminates pathogens while preserving beneficial microorganism activity.

Advanced fermentation technology can complete the maturation process in just 15-20 days, a task that traditionally required several months. By adding specialized microbial agents, fermentation efficiency significantly improves, enabling more thorough organic matter transformation.

Advanced Processing: From Mature Material to Premium Fertilizer

Fully matured materials enter the advanced processing stage. Crushers refine them to uniform particle sizes, after which disc granulators or drum granulators shape them according to target market requirements. During this process, functional microbial strains and trace mineral elements can be precisely added to produce bio-organic fertilizers with specific functions.

Post-Processing and Quality Control

Formed granules undergo low-temperature drying to preserve microbial activity, followed by cooling and screening to ensure uniform product particle size. Each batch undergoes rigorous laboratory testing, including indicators such as organic matter content, effective live bacteria count, and heavy metal content, ensuring compliance with national standards.

Modern organic fertilizer production lines achieve full automation control, with quality monitoring points established at every stage from raw material input to finished product packaging, guaranteeing final product stability and reliability.

Advancing to New Levels of Smart Agriculture

The success of modern organic fertilizer production lies not only in technological innovation but also in philosophical transformation. It converts agricultural waste into “black gold,” achieving resource recycling and providing solid support for sustainable agricultural development. With the deepening application of technologies like intelligent control and the Internet of Things, organic fertilizer production continues advancing toward more precise, efficient, and environmentally friendly directions.