The Screw Conveyor: The “Silent Artery” of the Fertilizer Production Line

In the complex ecosystem of fertilizer production, materials require stable, precise, and continuous conveyance. If the bucket conveyor is the conqueror of vertical space and the rotary screener is the meticulous quality sorter, then the Screw Conveyor is the “silent artery” that connects all links, ensuring an unimpeded and smooth production flow. With its simple yet highly efficient design, it plays an indispensable and foundational role silently under various complex working conditions.

Core Advantages: Flexible, Enclosed, Stable & Reliable

The appeal of the screw conveyor lies in its transformation of the simple principle of a rotating helix into a reliable solution for multiple scenarios.

Unmatched Layout Flexibility

The

Excellent Sealing and Environmental Performance

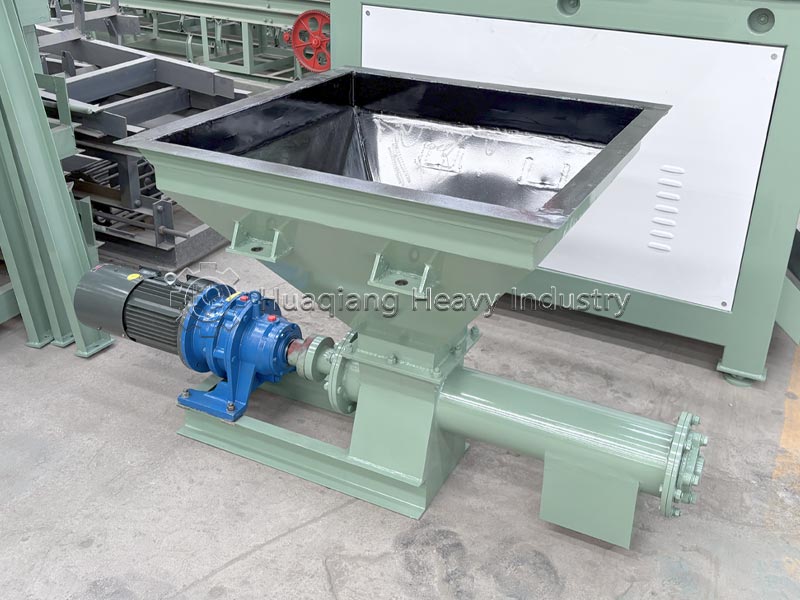

The design featuring a U-shaped trough or enclosed tube virtually eliminates dust and material leakage during conveying. This is crucial for protecting the working environment, preventing fertilizer loss through volatilization, and meeting the stringent environmental and safety standards of modern factories. It is the ideal choice for conveying powdered, granular, and small lump materials in enclosed settings.

Stable Controllability and Low Maintenance Costs

The material conveying rate can be precisely controlled by adjusting the rotational speed of the screw shaft, achieving uniform and metered feeding. This is of great significance for the stability of subsequent processes like mixing and packaging. Meanwhile, its simple structure with few core moving parts results in low failure rates and easy routine maintenance, significantly reducing long-term operational and upkeep costs.

Synergistic Production: The Universal Connector on the Line

The value of the screw conveyor is fully realized in its seamless collaboration with the entire range of fertilizer production equipment.

Paired with “Silos” and “Feeders”: Acts as a precise discharge and conveying unit, transferring stored raw materials steadily and controllably to the next process stage.

Serving “Mixers”: Simultaneously and accurately conveys various raw materials (e.g., N, P, K base fertilizers and trace elements) into the mixer according to preset ratios, a key link in ensuring formula accuracy.

Supporting “rotary drum granulator” and “Dryers”: Conveys materials with different moisture content before and after granulation. Its wear resistance and certain degree of temperature tolerance and sealing effectively adapt to the demanding requirements of such process stages.

Connecting to “Packaging Machines“: As the final conveying step, it smoothly transfers finished fertilizer into the hopper of the packaging machine, avoiding product breakage and ensuring precise, efficient bagging weight.

Evolution & Outlook: A Smarter, More Specialized Future

The traditional screw conveyor has already built a reputation for reliability and economy. Modern technological advancements are now infusing it with new vitality:

Intelligent Monitoring: Integration of sensors for real-time monitoring of torque, temperature, and fill level, enabling predictive maintenance and process optimization.

Material Innovation: Use of special stainless steels, wear-resistant liners, etc., to handle highly corrosive or abrasive materials.

Specialized Designs: Variants like high-incline screws and shaftless screws (ideal for viscous, easily entangled materials) continuously expand its application boundaries.

Conclusion

In summary, with its exceptional flexibility, outstanding sealing capability, and stable, cost-effective reliability, the screw conveyor has become a fundamental yet core conveying asset in modern fertilizer production lines. Like the “ligaments” and “blood vessels” of the production process, it may not always be in the spotlight, but it ensures the vitality and efficiency of the entire production system. As it evolves with intelligence and specialization, this classic piece of equipment will continue to innovate, providing solid support for the efficient, clean, and intelligent production of the global fertilizer industry.