What equipment is needed to build a small organic fertilizer production line?

How much does it cost to invest in a factory that processes cow dung into organic fertilizer? To invest in a cow dung organic fertilizer production line, the investment amount includes the following aspects: site rental fees, building a factory, purchasing organic fertilizer processing equipment, purchasing manure, workers’ wages, and the total amount of water and electricity fees? Don’t worry, let’s take a look together.

According to relevant policies, organic fertilizer factories cannot be built in the city center or near residential buildings, so the factory sites are mostly located in industrial parks or rural areas that are slightly away from the processing raw materials. Generally, the price will not be too high, because most of them belong to Class III industrial land. The rent of more than 600 square meters is about 100,000-150,000.

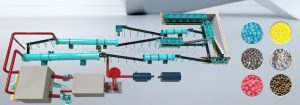

Regardless of whether the raw materials for organic fertilizer processing are chicken manure, cow manure, pig manure, or sheep manure, the production line equipment for organic fertilizer processing includes: trough turner, semi-wet material crusher, mixer, granulator, dryer, cooler, screening machine, packaging machine, etc. Small organic fertilizer production line can be selected to produce 10,000 tons of organic fertilizer per year.