Windrow Compost Turning Machine: The Science Behind Composting Art

In the magical journey where organic waste transforms into premium compost, the windrow compost turning machine plays the vital role of a “magician”. This seemingly bulky steel beast actually embodies sophisticated bioengineering wisdom. Let’s unveil the mystery of its efficient operation.

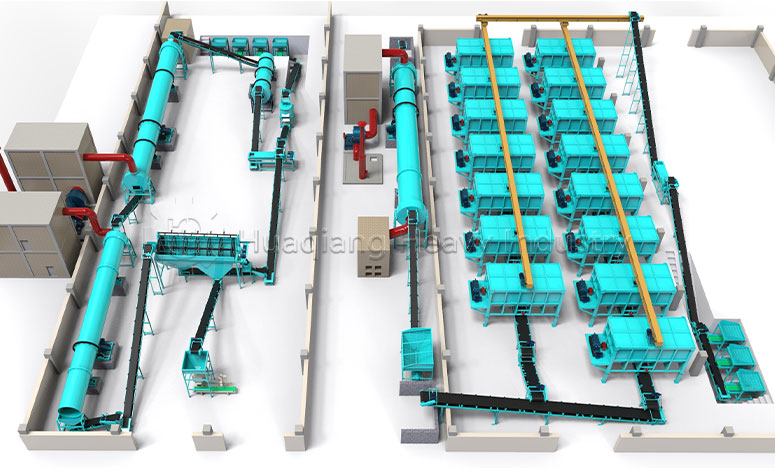

The windrow compost turning machine is fundamental to organic fertilizer production processes, accelerating decomposition to create high-quality compost. In complete fertilizer production lines, it serves as the crucial first step, transforming raw organic waste into stable humus for subsequent granulation. Its operation directly impacts the efficiency and quality of the entire organic fertilizer manufacturing system.

Step 1: Penetrating the Material Core

1As the windrow compost turning machine moves slowly through the compost windrow, its specially designed turning mechanism penetrates deep into the material like a surgical scalpel, reaching depths of 1.5-2 meters. This deep intervention ensures uniform treatment of all material layers, avoiding the “partially cooked” phenomenon common with traditional shallow turning.

Step 2: The Art of Turning

2The high-speed rotating mixing arm drives specially designed blades to lift and scatter materials at precise angles. This seemingly simple action is actually meticulously calculated: the lifting height ensures adequate aeration, the scattering angle creates ideal porosity, while rotation speed control prevents excessive organic matter fragmentation.

Key Innovation: Modern turners feature “bionic blades” that mimic earthworm movements, simultaneously accomplishing crushing, mixing and aeration during the turning process, improving efficiency by 40%.

Step 3: Creating the Perfect Microenvironment

3Each turning is a precise microenvironment adjustment: moving overheated core materials outward to cool, shifting under-fermented edge materials into hot zones, while introducing fresh air. This “material rotation” mechanism creates uniform aerobic conditions that boost beneficial microbial activity.

Step 4: Intelligent Fermentation Management

4Advanced models equipped with smart sensors can monitor material temperature and moisture in real-time, automatically adjusting turning frequency and depth. This data-driven precision management can shorten traditional 45-60 day fermentation cycles to 20-30 days, with more consistent compost quality.

Step 5: Continuous Optimization Cycle

5After 5-7 such turning cycles, organic materials complete their transformation from waste to “black gold”. Throughout the process, the turner serves not just as an executor, but as a regulator and optimizer of the fermentation process.

The working process of a windrow compost turning machine is a perfect dance between mechanical and biological forces. Using its steel body to execute the most precise bioengineering, it transforms agricultural waste into precious resources that nourish the land – this is the most moving poetry of modern agricultural technology.