Core Processes and Quality Control Points in Organic Fertilizer Production

Organic fertilizer, as a key link connecting the resource utilization of agricultural waste and ecological farming, involves the scientific optimization and industrial scaling of natural microbial decomposition. Unlike the synthesis of chemical fertilizers, organic fertilizer production uses natural materials such as manure and plant waste as core raw materials. Through a series of standardized industrial processes, unstable organic waste is transformed into a stable product rich in humus, with balanced nutrients and soil-friendly properties. Precise control of key parameters such as moisture, temperature, and carbon-nitrogen ratio is required throughout the process to ensure efficient microbial metabolic activity.

Raw material collection and pretreatment are fundamental steps in organic fertilizer production, directly determining the nutritional basis and safety of the product. Raw material sources must be strictly screened. Animal manure should primarily come from large-scale livestock farms, such as cattle, sheep, and chicken manure, and impurities such as stones and plastics must be removed beforehand. Plant waste includes crop straw, vegetable residues, oil palm empty fruit bunches, and oil cakes. Agricultural by-products such as oil palm empty fruit bunches require preliminary crushing to improve subsequent fermentation efficiency. The core task of the pretreatment stage is raw material ratio adjustment. Materials are mixed according to their different carbon-nitrogen ratios; for example, high-carbon materials like straw need to be combined with high-nitrogen materials like manure to adjust the overall carbon-nitrogen ratio to the optimal range of 25:1-30:1. Simultaneously, moisture content is adjusted to 55%-65% through drying or adding water to provide a suitable environment for microbial growth. For raw materials with a higher risk of contamination, a disinfection pretreatment step is also necessary to reduce the probability of pathogen residue.

Fermentation/composting is the core process of organic fertilizer production, divided into two main modes: aerobic fermentation and anaerobic fermentation. Its essence is the decomposition and transformation of organic matter by microorganisms. Aerobic fermentation is suitable for large-scale production and requires regular turning of the compost pile using a turning machine to ensure sufficient oxygen supply. The temperature of the compost pile gradually rises to 50-60℃ due to microbial metabolic activity. This temperature range not only accelerates the decomposition of organic matter but also effectively kills pathogens such as E. coli and roundworm eggs in the manure. Turning and fermentation typically continue for 20-30 days until the pile temperature drops and the material becomes dark brown and loose. Anaerobic fermentation is mostly used in small-scale production or for processing specific materials, such as the Bokashi fermentation system. This process requires mixing raw materials with molasses and EM microbial agents, then sealing and covering the mixture to isolate it from air and promote the reproduction of anaerobic microorganisms. Although the fermentation cycle is relatively short (7-15 days), it requires appropriate turning of the mixture during the middle of the fermentation process to release accumulated harmful gases and replenish a small amount of oxygen, preventing incomplete fermentation. Parameter control during this stage is crucial. Moisture content is determined by a squeeze test; the ideal consistency is when the material forms a ball when squeezed but crumbles when released. Temperature needs to be monitored in real-time; if it falls below 50℃, the turning interval should be reduced, and if it exceeds 65℃, the turning intensity should be increased to lower the temperature and prevent the inhibition of microbial activity.

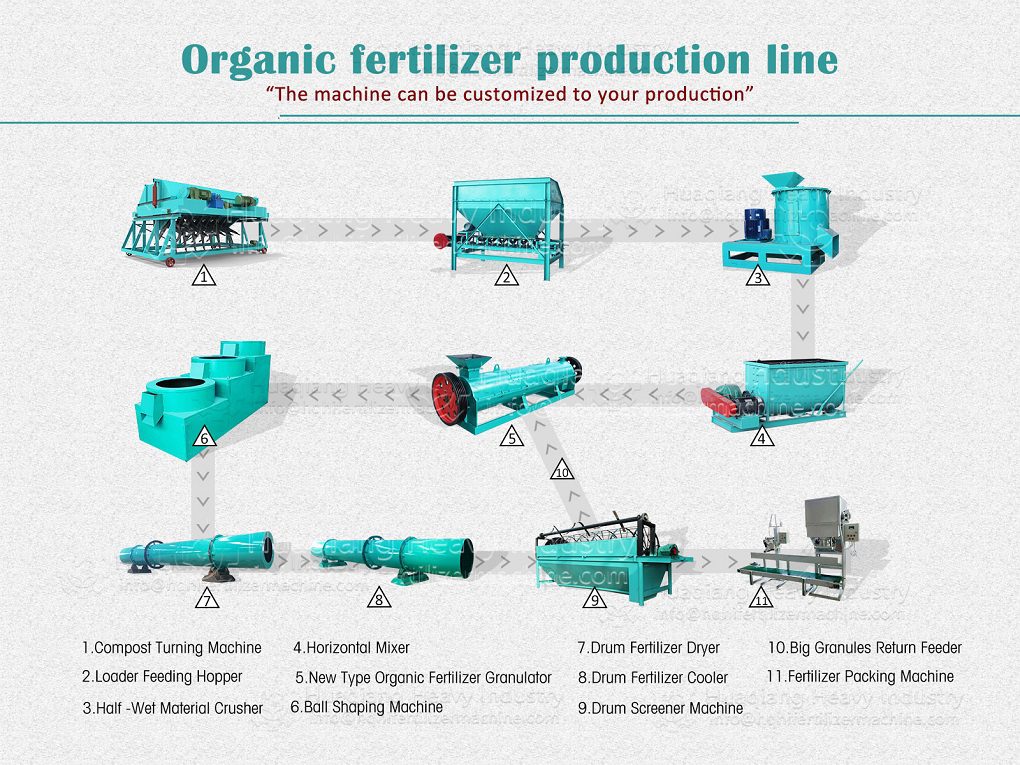

Subsequent processes of crushing, mixing, granulation, drying, cooling, and screening and packaging primarily serve to optimize the product’s form and storage stability. The crushing stage involves grinding the fermented and matured material into a powder of 80-100 mesh to ensure even distribution of nutrients. The mixing stage allows for the addition of appropriate trace element fertilizers and biological microbial agents, depending on the product’s intended use, to enhance the fertilizer’s targeted effects. A small amount of binder is also added to improve granulation performance. The granulation process uses a specialized granulator to produce uniform granules with a diameter of 2-4 mm, which facilitates field application and measurement while reducing dust pollution during transportation. The drying stage reduces the moisture content of the granules to below 12%, usually using low-temperature hot air drying to avoid high temperatures that could damage humus and other effective components. After cooling, screening equipment separates fine particles and impurities. Fine particles can be returned to the granulation process for recycling, while qualified granules are quantitatively packaged. Before packaging, the product’s organic matter content, pH value, and other indicators are tested to ensure compliance with national organic fertilizer standards. Throughout the entire process, quality control is essential, from raw material testing to finished product sampling, forming a complete quality traceability system to guarantee the safety and effectiveness of the organic fertilizer.

Advanced Systems for Modern Organic Fertilizer Production

The final stages of the organic fertilizer manufacturing system focus on transforming the cured compost into a consistent, marketable product. After crushing and mixing, the organic fertilizer production granulation phase is critical. Here, producers can choose from several technologies based on raw material characteristics and desired output. A traditional and effective method is the organic fertilizer disc granulation production line, where the moist powder is fed onto a rotating disc, forming spherical granules through a tumbling and layering mechanism. Alternatively, a flat die pelleting machine uses extrusion pressure to create cylindrical pellets, offering high density and strength. For facilities seeking space efficiency and process simplification, a new type two in one organic fertilizer granulator combines the mixing and granulation steps in a single machine, enhancing operational efficiency. An integrated organic fertilizer combined granulation production line may sequentially employ different granulators to achieve optimal particle structure.

This granulation flexibility is central to a complete organic fertilizer production line. When the process is designed to incorporate specific functional microbial consortia post-fermentation, it evolves into a sophisticated bio organic fertilizer production line. The entire system’s efficacy, however, is fundamentally reliant on the quality of the compost feedstock produced upstream by advanced fermentation composting turning technology, typically executed by robust equipment like a chain compost turning machine in windrow systems. Ultimately, selecting the right combination of an organic fertilizer disc granulation machine and supporting equipment defines the efficiency and product quality of the entire organic fertilizer manufacturing operation.

This integrated approach—from controlled aerobic fermentation to precision granulation—ensures that the final product is not only nutrient-rich but also possesses excellent physical properties for storage, transport, and soil application, meeting the demands of modern, sustainable agriculture.