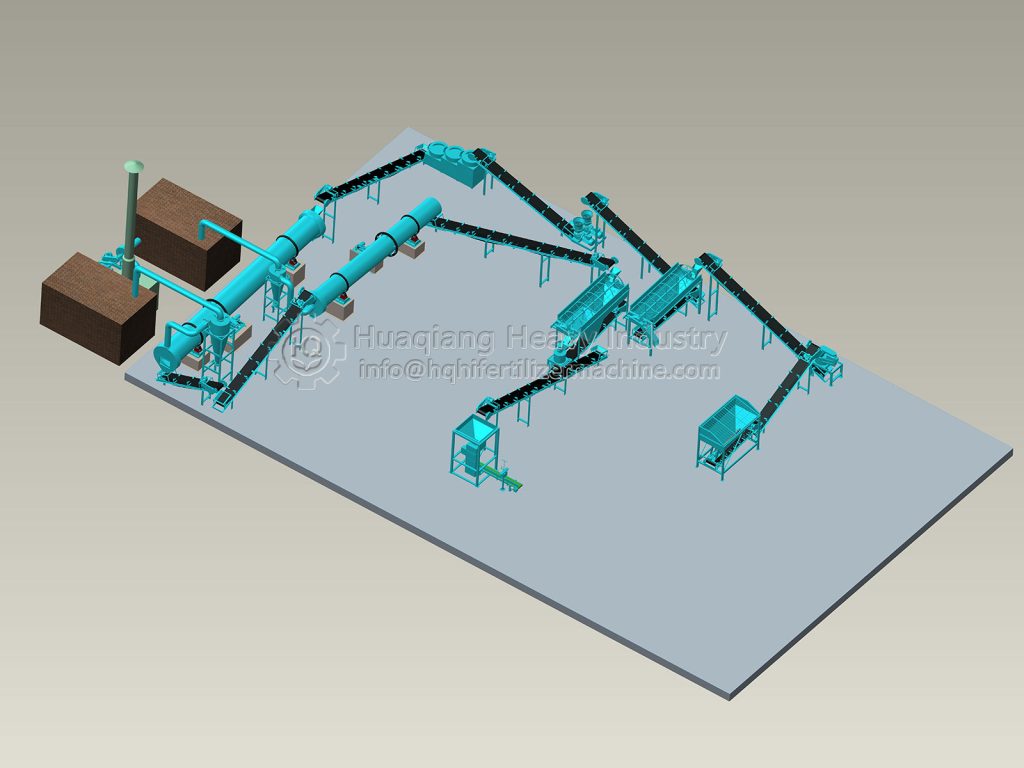

Complete Process of Livestock Manure Fertilizer Production

Transforming livestock manure into high-quality organic fertilizer not only addresses the challenge of farming waste disposal but also provides excellent soil amendments for agricultural production. This conversion process requires strict harmless treatment and scientific processing techniques.

Raw Material Pretreatment Stage

Raw material pretreatment is the foundational link of the entire production process. First, solid-liquid separation is necessary, where high-moisture manure such as pig and cattle waste is separated using specialized equipment to achieve an ideal solid material moisture content of 60%-65%. Next, impurities including feathers, plastic fragments, and other foreign matter are removed to ensure safe operation of subsequent equipment. Finally, by adding carbon source materials like straw and sawdust, the material’s carbon-to-nitrogen ratio is adjusted to the optimal range of 25:1-30:1.

Aerobic Fermentation Process

Aerobic fermentation is the core step in achieving harmless treatment. The pretreated material is piled into windrows or fed into fermentation tanks, and regularly turned using turning machines to ensure adequate oxygen supply. During fermentation, the temperature rises to 55℃-70℃ and is maintained for 5-7 days, effectively killing pathogenic bacteria and insect eggs.

Signs of completed fermentation include: temperature dropping to ambient levels, material color turning dark brown, emitting an earthy fragrance, and significant volume reduction. At this stage, the material has become stable, decomposed organic fertilizer.

Crushing and Screening Processes

The fermented material requires crushing treatment, using hammer mill crushers to control particle size to 20-40 mesh. The crushed material is then graded through vibrating screens to separate qualified fine powder from incompletely decomposed coarse fibers. Coarse fibers can be returned for re-crushing or used as bedding material in farms, achieving resource recycling.

Formulation and Granulation Technology

According to the nutrient requirements of the target product, necessary additives are mixed into the organic fertilizer fine powder. Common additives include chemical fertilizer materials like urea and monoammonium phosphate, as well as binders such as bentonite. The formulation process uses electronic weighing systems for precise control to ensure stable product quality.

The granulation process selects different techniques based on product requirements. Extrusion granulation is suitable for materials with lower moisture content, producing high-strength granules; while disc granulation is more appropriate for materials with slightly higher moisture content, producing round and uniform granules. Both processes have their advantages and can be chosen according to specific needs.

Drying, Cooling and Final Product Processing

Freshly produced granules require drying treatment to reduce moisture content to 10%-12%, followed by cooling equipment to bring the temperature down to ambient levels. This process is crucial for product storage stability.

Final product processing includes screening and grading, quantitative packaging, and quality testing. Uniform granule size is ensured through vibrating screens, precise measurement is achieved with automatic packaging machines, and finally, strict quality inspections are conducted to ensure products meet national standard requirements.

Livestock manure fertilizer production is a systematic project where each link directly affects the quality of the final product. Through scientific process flows and strict quality control, not only can farming pollution problems be effectively solved, but high-quality organic fertilizers can also be produced, achieving a win-win situation for both economic and environmental benefits.

Conclusion

The transformation of livestock manure into high-quality organic fertilizer represents a sophisticated integration of agricultural waste management and sustainable manufacturing. The complete organic fertilizer production line encompasses multiple critical stages, beginning with efficient organic fertilizer fermentation accelerated by specialized equipment like the chain compost turner and large wheel compost turning machine. Following decomposition, the material progresses through various granulation technologies where the organic fertilizer granulator plays a pivotal role in shaping the final product. Different fertilizer granulator options are available, including the double roller press granulator for compacted granules and the rotary drum granulator for spherical particles through drum granulation. For operations requiring combined nutrient profiles, the npk fertilizer production line utilizes specialized npk fertilizer granulator equipment within the comprehensive npk production process. The fertilizer roller press machine offers an alternative approach to granulation, while specialized systems like the bio organic fertilizer production line cater to microbial-enhanced products. Throughout the npk fertilizer manufacturing process and organic fertilizer production, equipment such as the wheel compost turner and drum granulator ensure efficient operation from raw material to finished product. This integrated approach to fertilizer manufacturing not only solves environmental challenges but creates valuable soil amendments, demonstrating how modern technology can transform waste into resources while supporting sustainable agriculture.