Fertilizer granulator is a key tool in the Npk fertilizer production line

Introduction

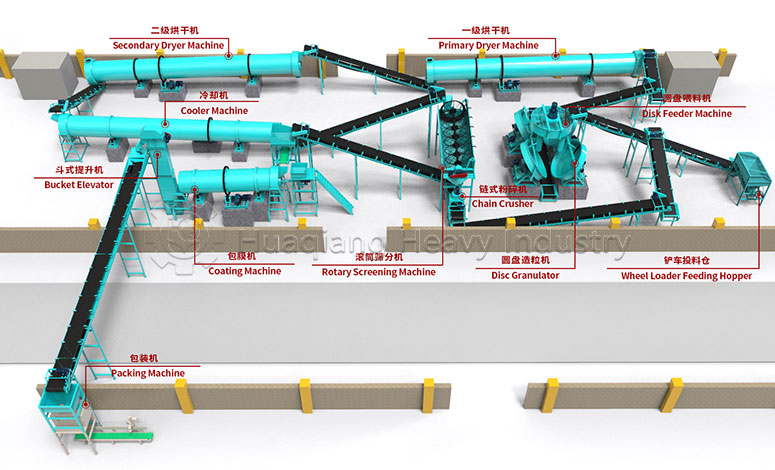

In the production of fertilizer granules, whether it is producing compound fertilizer granules or granulating powdered materials after fermentation and composting, the fertilizer granulator is a key equipment.

Working Principle of Fertilizer Granulator

Fertilizer granulation is the process of converting powdered or liquid fertilizer raw materials into granular products of a specific shape and size through physical or chemical methods. Granulation technology not only improves the physical properties of fertilizers but also increases their efficiency and economic benefits. Fertilizer granulators primarily use extrusion and rolling to form powdered fertilizers into granules or columns.

Our company provides a variety of granulation equipment such as disc granulator, drum granulator, double roller press granulator, etc. to meet the different requirements of customers.

A disc granulator uses a tilted disc to roll powdered fertilizer into granules. With its simple structure and low energy consumption, it’s ideal for small- to medium-scale fertilizer granulation.

A rotary drum granulator uses a rotating drum to aggregate and shape the material. It offers high production capacity and a high pelletization rate, making it ideal for large-scale fertilizer granulation.

A double roller press granulator uses mechanical pressure to force the material into granules. It requires no drying, is energy-efficient, and is environmentally friendly, making it suitable for granulating high-, medium-, and low-concentration compound fertilizers.

Fertilizer Granulator Selection Guide

- Based on the raw material characteristics

Powdered raw materials are suitable for drum granulators and disc granulators. High-hardness formulas are recommended for double roll press granulators.

- Based on the production scale

For small-scale production, a disc granulator is recommended. For large-scale production, a rotary drum granulator or a double roller press granulator is recommended.

Fertilizer granulation technology will become a core competitive advantage in the industry. Selecting the right granulation equipment and optimizing the production process will not only improve product quality but also significantly reduce production costs.