Organic Fertilizer Production Line: The Amazing Transformation from Waste to Nutrient Granules

Exploring how modern organic fertilizer production equipment transforms agricultural waste into efficient fertilizers, achieving resource recycling and sustainable development

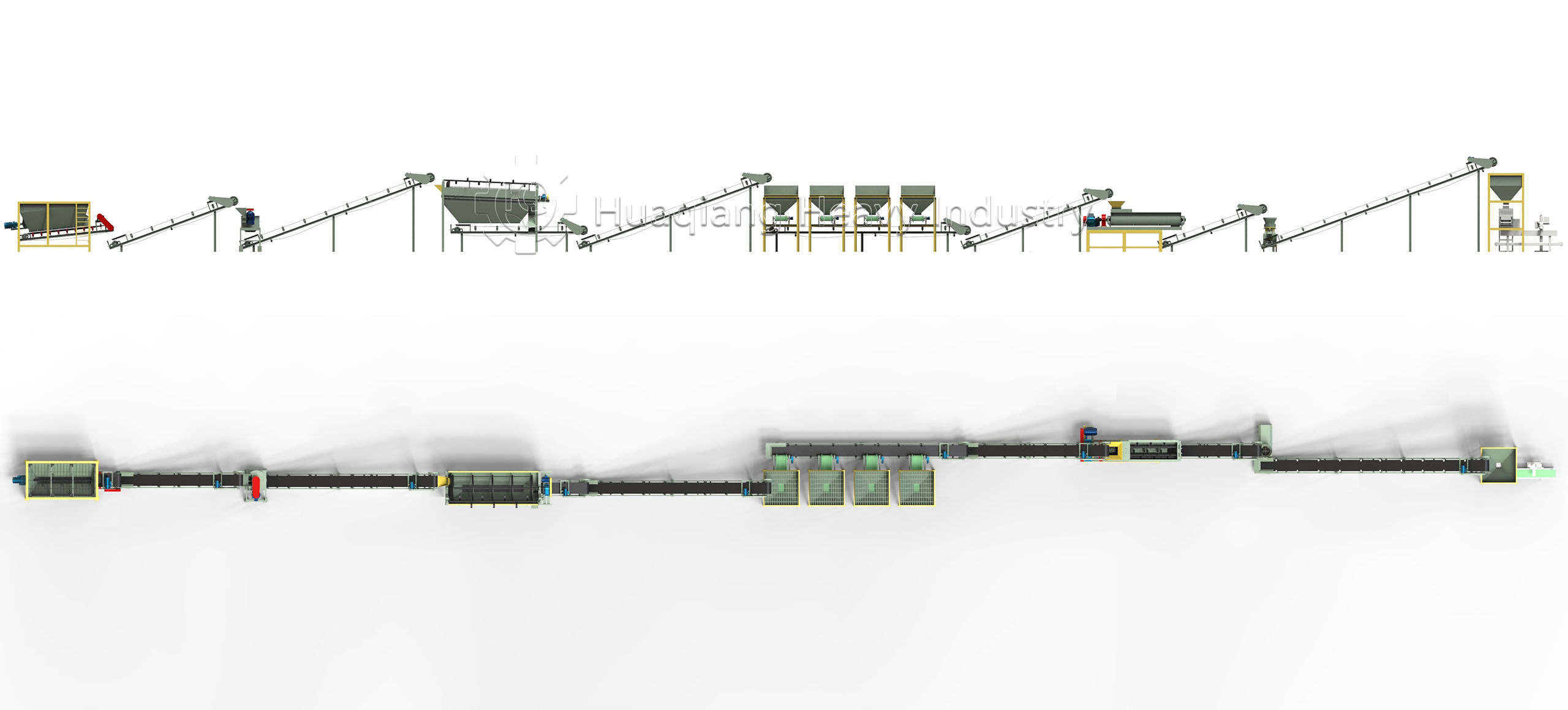

The Complete Ecosystem of Organic Fertilizer Production

Have you ever wondered how seemingly useless agricultural waste transforms into valuable resources that nourish crops? Modern organic fertilizer production line systems function like precision “conversion factories,” turning waste into efficient organic fertilizers through a series of carefully designed equipment and processes. At the heart of this transformation lies the sophisticated organic fertilizer granulator, which plays a pivotal role in creating uniform, high-quality fertilizer products.

The versatility of the modern fertilizer granulator allows for adaptation to various material characteristics and production requirements. Among the most efficient systems is the rotary drum granulator, which utilizes its unique tumbling motion to create perfectly spherical organic fertilizer granules. This specialized equipment within the comprehensive organic fertilizer production line ensures optimal nutrient consistency and product quality.

The entire organic fertilizer manufacturing process, powered by these advanced granulation technologies, not only addresses environmental pollution concerns but also creates significant economic value. From waste management to crop nourishment, the integrated system featuring specialized granulation equipment demonstrates how innovative technology can transform sustainability challenges into valuable agricultural solutions.

Core Equipment Composition: A Synergistic Precision System

Raw Material Pre-treatment System

Crushers and screening machines work together to break down large organic waste and remove impurities, creating ideal conditions for subsequent fermentation. This step is like preparing a “delicious meal” for microorganisms, ensuring efficient fermentation.

Fermentation Conversion System

Compost fermentation turners and fermentation tanks transform organic waste into stable organic matter through microbial action. This process not only eliminates pathogens and weed seeds but also activates the biological activity in the fertilizer.

Turning and Aeration System

Compost turners regularly flip the compost piles, essentially “providing fresh air” for microorganisms, ensuring adequate oxygen supply, promoting microbial activity, and significantly accelerating the fermentation process.

Granulation Forming System

The organic fertilizer granulator is the heart of the production line, processing fermented organic matter into granular fertilizers through disc granulators or rotary drum granulators. This step not only enhances the product’s commercial value but also facilitates storage and application.

Granulation Technology Comparison: The Synergy Between Double Roller Press Granulators and Rotary Drum Granulators

In NPK fertilizer production technology, double roller press granulators and rotary drum granulators each play unique and important roles. Interestingly, these technologies have also found their place in organic fertilizer production lines, forming perfect technical complements.

Double Roller Press Granulator

In NPK fertilizer production, double roller press granulators use powerful mechanical pressure to directly compress powdered raw materials into granules, particularly suitable for high-concentration compound fertilizers. In organic fertilizer production lines, this technology is equally applicable, especially for processing organic materials with high fiber content, producing denser and stronger granular fertilizers.

Rotary Drum Granulator

Rotary drum granulators are known for their gentle granulation process in NPK fertilizer production technology, forming granules through material rolling and agglomeration. In organic fertilizer production, this equipment is particularly suitable for processing sticky organic materials, producing granules with better roundness and improved solubility.

The combined use of both granulation technologies enables organic fertilizer production lines to process more diverse raw materials and produce fertilizer products that meet various needs. This technological integration not only enhances production flexibility but also ensures product quality stability.

Post-processing and Packaging: The Final Quality Assurance

After granulation, fertilizers undergo post-processing steps including drying, cooling, and screening. Drying equipment removes excess moisture, cooling equipment prevents high temperatures from affecting fertilizer efficiency, and screening equipment ensures uniform particle size. Optional coating equipment applies a protective film to the granule surface, improving moisture resistance and controlled-release properties. Finally, automatic packaging machines complete precise weighing and packaging, ensuring products reach users in optimal condition.

Intelligent Control System: The Brain of the Production Line

PLC control systems and automation instruments act as the “intelligent brain” of the production line, monitoring and adjusting key process parameters in real-time. This intelligent management not only ensures stable operation of the production line but also significantly improves production efficiency and product quality consistency.

Core Technology Connections: Organic Fertilizer Granulator · Organic Fertilizer Production Line · Organic Fertilizer Production · Double Roller Press Granulator · Rotary Drum Granulator · NPK Fertilizer Production Technology · Sustainable Development