Screening Machines: Fertilizer Quality Guardians

The Golden Combination of Drum and Vibrating Screeners

In modern fertilizer production lines, drum screener machines and vibration screener machines work like a well-coordinated “golden duo,” jointly guarding the final defense line of product quality. The drum screener is renowned for its gentle screening approach, particularly suitable for fragile materials – it operates like a patient gardener, gradually classifying fertilizer particles by size through slow rotation.

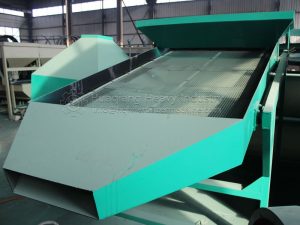

Meanwhile, the vibrating screener functions as an efficient quality inspector, rapidly separating particles of different specifications through high-frequency vibration with remarkable processing capacity. The perfect collaboration between these two creates a synergistic effect exceeding the sum of its parts.

This combined system can boost production efficiency by over 40% while maintaining substandard rates below 0.5%, making it an indispensable “quality gatekeeper” for large-scale fertilizer plants.

Central Role in NPK Production

In NPK compound fertilizer manufacturing, screening machines are far from optional auxiliary equipment – they represent a crucial link determining product quality. After granulation, unevenly sized NPK particles must undergo rigorous screening to ensure consistent nutrient release rates.

Here, the drum screener serves as a “grading master,” returning oversized particles for re-granulation, directing qualified particles to the coating process, and recycling fine powder.

Particularly noteworthy are modern intelligent screening systems that can automatically adjust mesh apertures, modifying classification standards in real-time according to different formula requirements. This smart upgrade significantly enhances production line flexibility, enabling a single set of equipment to manufacture various product specifications with 80% shorter changeover time.

Special Value in Organic Fertilizer Production

For organic fertilizer production, the importance of screening machines is even more undeniable. Unscreened organic fertilizer not only appears unappealing but also affects application effectiveness. Vibrating screeners demonstrate unique advantages here, with their efficient screening capability effectively removing impurities and insufficiently fermented materials, markedly improving product quality.

In organic fertilizer lines, screening machines also assume the role of “final quality controller.” Properly screened organic fertilizer features uniform particles, ensuring both product aesthetics and stable nutrient release.

Many premium organic fertilizer producers even adopt three-stage screening systems to classify products into premium, first, and second grades, maximizing product value.