The Granulation Journey: From Waste to Nutrient Treasure

Discover how modern organic fertilizer production lines transform agricultural waste into efficient nutrient granules through precision processes, opening a new chapter in sustainable agriculture

The Magical Transformation: From Waste to Nutrient Granules

Have you ever imagined how discarded livestock manure, crop straw, and food processing residues could undergo a magnificent transformation into valuable resources that nourish the land? This is not just resource recycling, but the wonderful art of modern organic fertilizer production. The entire organic fertilizer production process resembles a carefully orchestrated symphony, where each step plays an indispensable role.

The Carefully Prepared Overture: Raw Material Pre-treatment

1 – Intelligent Collection and Classification

The organic fertilizer production journey begins with precise raw material collection. Like treasure hunters, we gather various organic wastes from farms, food processing plants, and other sources, conducting scientific classification. This meticulous sorting not only lays the foundation for subsequent processing but also ensures the stability of raw material quality.

2 – Precision Crushing and Mixing

Using advanced crushing equipment, we process large raw materials into ideal particle sizes suitable for fermentation. Subsequently, materials are mixed according to scientific ratios to optimize the carbon-nitrogen ratio, much like preparing a “nutritious feast” for microorganisms, creating optimal conditions for efficient fermentation.

The Metamorphosis of Life: The Art of Fermentation

3 – The Magic of Compost Fermentation

Within carefully designed fermentation areas, raw materials begin their miraculous transformation under microbial action. Whether through natural fermentation or artificially controlled heating processes, pathogens and weed seeds are silently eliminated while complex organic matter is broken down into forms easily absorbed by plants.

4 – Precision Process Control

Through real-time monitoring of temperature, humidity, and oxygen levels, we carefully regulate the fermentation environment like attentive gardeners. Regular turning not only provides sufficient oxygen but ensures every part of the raw material ferments uniformly – this is key to guaranteeing product quality.

The Essence of Granulation: From Powder to Perfect Granules

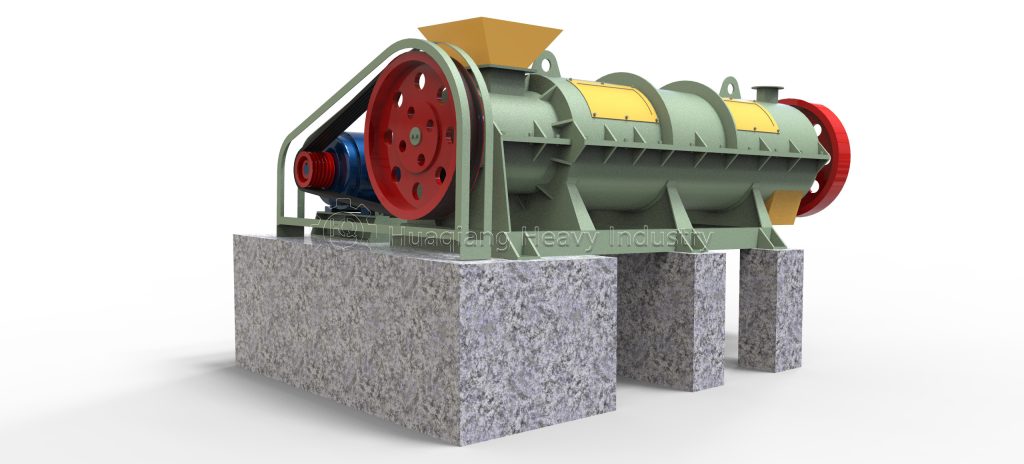

After fermentation, materials undergo further screening and crushing to remove undecomposed impurities, then enter the most exciting phase of the entire organic fertilizer production process – granulation. In advanced organic fertilizer granulators, powdered raw materials gradually take shape under precise control, transforming into uniform granules. This transformation not only significantly enhances the product’s commercial value but makes fertilizer storage, transportation, and application exceptionally convenient.

Modern organic fertilizer production lines are equipped with complete post-processing systems: drying processes remove excess moisture to prevent caking; cooling ensures appropriate product temperature; fine screening guarantees uniform particle size; optional coating processes can form protective layers on granule surfaces, achieving controlled nutrient release effects.

The Perfect Finish: Quality Assurance and Storage

5 – Intelligent Packaging and Quality Inspection

Automatic packaging machines precisely complete weighing and packaging, with each bag carrying a commitment to quality. Strict quality testing ensures products meet relevant standards – from nutritional content to physical characteristics, no detail is overlooked.

6 – Scientific Storage and Transportation

Qualified organic fertilizers are properly stored in dry, ventilated warehouses, waiting to contribute to the next season’s harvest. Scientific storage management ensures products maintain optimal quality when they reach farmers.

Core Technology System: Organic Fertilizer Granulator · Organic Fertilizer Production Line · Organic Fertilizer Production · Sustainable Development · Resource Recycling · Precision Agriculture