Turning Pig Manure into Gold: Organic Fertilizer Line Revealed

In the wave of circular agriculture, pig manure has transformed from a troublesome waste into a precious organic resource. How does this magical production line convert malodorous pig manure into high-quality organic fertilizer? Let’s uncover the secrets of this green alchemy.

The quoted text serves as an engaging introduction to bio-organic fertilizer production lines, highlighting their transformative role in circular agriculture. It specifically references how these production systems convert problematic pig manure – previously considered waste – into valuable organic fertilizer through a series of specialized processes, setting the stage for a detailed explanation of the production line’s components and operations.

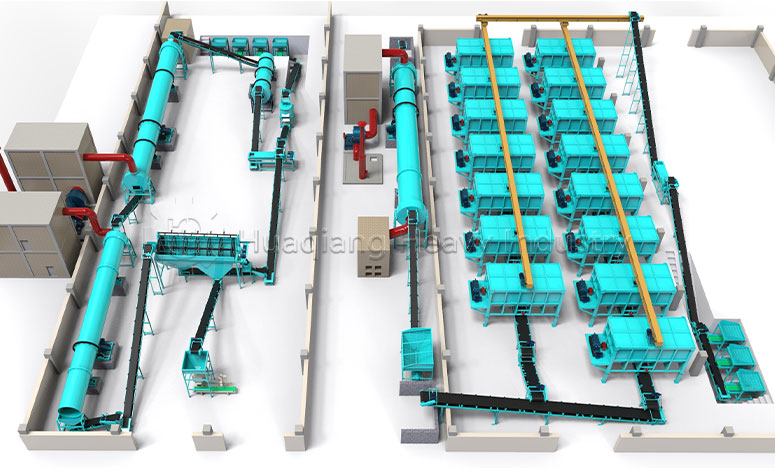

“From composting to packaging, eight processes complete the perfect transformation of agricultural waste”

Symphony of Core Equipment

Semi-wet Material Crusher

High-efficiency Mixer

New Organic Fertilizer Granulator

Rotary Dryer

Multi-layer Screener

Belt Conveyor

Intelligent Coating Machine

Automatic Packing Machine

Fermentation Process: 72 Hours of Natural Magic

Step 1: Raw Material Preparation

Fresh pig manure with 70% moisture content is mixed with dry auxiliary materials (straw, sawdust etc.) at a 3:1 ratio, supplemented with special fermentation agents. Like preparing a feast for microorganisms, this ratio ensures perfect carbon-nitrogen balance, laying the foundation for subsequent fermentation.

Step 2: High-temperature Fermentation Miracle

Windrow composting is the most exciting phase. Temperatures rapidly rise to 50-70°C within 24-36 hours, not only killing pathogens but also achieving complete deodorization in three days. This naturally occurring “biological boiler” phenomenon is the best proof of microbial activity.

Three Advantages of Pig Manure Organic Fertilizer:

- Soil Improvement: Up to 45% organic matter content significantly improves soil structure

- Eco-friendly: Achieves 100% resource utilization of farming waste

- Yield & Quality Boost: Increases crop yield by 15-20% with noticeable quality improvement

Precision Processing: From Compost to Premium Fertilizer

After 15 days of fermentation, materials undergo crushing, granulation, drying, and screening to become uniform premium organic fertilizer. The new organic fertilizer granulator uses gentle pressure forming technology, ensuring granule strength while preserving 100% active bacteria.

From avoided waste to sought-after organic fertilizer, this production line not only creates economic value but also achieves a perfect closed loop in agricultural circular economy.