Microbial Feast: How Does Bio-Organic Fertilizer Undergo a Stunning Transformation?

Imagine if organic waste could speak—what stories of rebirth would it tell? In the magical factories of modern agriculture, these seemingly useless materials are undergoing an astonishing transformation—from overlooked byproducts to precious fertilizers that nourish the earth. This is not just a production line; it’s a vibrant ecosystem.

Daily, tons of agricultural residues, food processing waste, and livestock manure embark on this journey of transformation. They are not mere “garbage” but valuable resources rich in carbon, nitrogen, phosphorus, potassium, and other elements. The efficient crushing system acts like a meticulous artist, breaking down these materials into uniform particles, preparing them for subsequent transformation.

The Awakening of Raw Materials

Simultaneously, the intelligent batching system precisely calculates the proportions of various raw materials, ensuring balanced nutrition in the final product. This precise batching process resembles an experienced chef preparing a complex meal—each ingredient must be just right.

Raw Material Collection

Organic materials like agricultural waste and food processing byproducts

Crushing Process

Breaking raw materials into uniform particles, increasing surface area

Intelligent Batching

Precise calculation of carbon-to-nitrogen ratio, optimizing nutritional composition

The Symphony of Microorganisms

In temperature-controlled fermentation tanks, a grand symphony of microorganisms is underway. Billions of bacteria, fungi, and actinomycetes work together, decomposing complex organic molecules into simple forms that plants can absorb. This process is vibrant—temperatures gradually rise, moisture is regulated, oxygen is precisely controlled, all to maximize the potential of these tiny life forms.

Advanced fermentation systems such as large wheel compost turning machine can even simulate the optimal conditions of natural composting, reducing a process that takes months to just weeks. Here, technology does not replace nature but optimizes natural processes, allowing microorganisms to fulfill their mission in the most suitable environment.

The Shaping of Form

After fermentation, the material enters the granulation stage. This phase is full of creativity—organic materials are shaped into uniform, stable pellets through various processes. new type two in one organic fertilizer granulator work like potters, shaping powder into perfect spheres through rotation and spraying; extrusion granulators resemble pastry chefs, creating various shapes through molds.

The subtlety of this stage lies in balance: the pellets must be sturdy enough to withstand transportation and storage, yet not too dense to affect nutrient release. Modern granulation technology finds this perfect balance by controlling moisture, pressure, and temperature.

The Art of Synergy

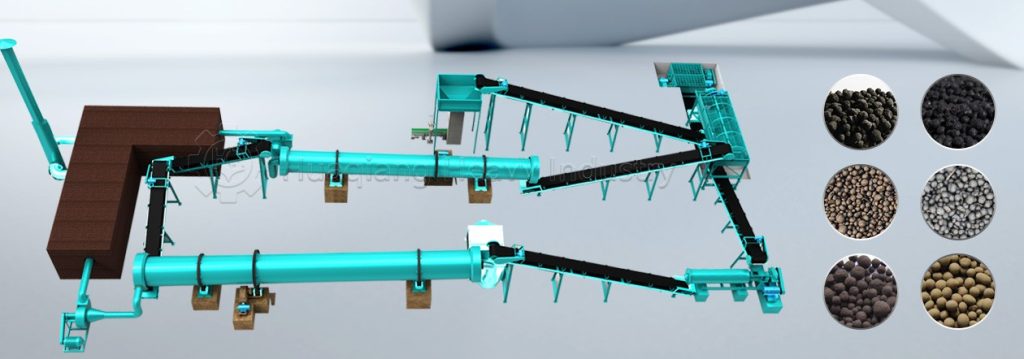

What truly sets this production line apart is the seamless collaboration between equipment. Each component is like an instrument in an orchestra—beautiful when played alone, but truly magical when performed together.

Crushing & Mixing Systems

Create ideal conditions for fermentation

Intelligent Fermentation Devices

Core conversion equipment, the stage for microorganisms

Multifunctional Granulation Equipment

Provide products with ideal form and structure

Drying & Cooling Units

Ensure product stability and shelf life

A New Dimension of Intelligence

Modern bio-organic fertilizer production line have entered the intelligent era. IoT sensors collect data in real-time, AI algorithms optimize production parameters, and automation systems reduce human intervention. Operators can monitor the entire production process via tablets, receive real-time alerts, and even make adjustments remotely.

This intelligence not only enhances production efficiency but ensures product consistency and traceability—every step from raw material sourcing to final product is meticulously recorded.