Bio-Organic Fertilizer Production Line: Where Nature Meets Technology

Have you ever wondered about the fascinating journey behind a bag of nutrient-rich bio-organic fertilizer? From organic waste materials to efficient, environmentally friendly fertilizer, this transformation is powered by a sophisticated bio-organic fertilizer production line—a perfect marriage of natural cycles and modern technology.

Nature’s Gift Enhanced by Technology

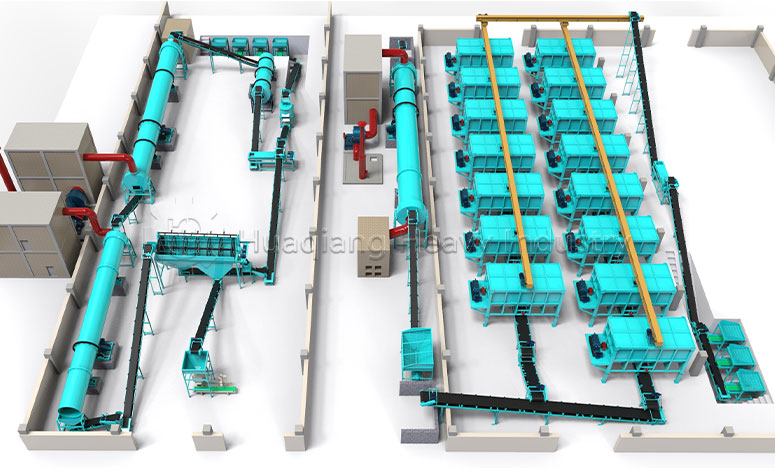

The core of a bio-organic fertilizer production line lies in converting organic materials like agricultural waste, livestock manure, and kitchen scraps into stable, effective fertilizer. This production line is not merely a collection of machines but a synergistic ecosystem where each piece of equipment plays an indispensable role.

The process begins with crushing and pre-treatment. Efficient crushers break down various organic raw materials into uniform, fine particles, laying the foundation for subsequent fermentation and granulation. Next, the mixing and proportioning system precisely blends different raw materials in scientific ratios to ensure balanced nutrition in the final product.

Fermentation: The Magic of Life

The heart of the production line is the fermentation system. Here, microorganisms work their natural magic, decomposing organic matter into nutrients readily absorbable by plants. Modern fermentation equipment such as large wheel compost turner creates ideal conditions for microbial growth by precisely controlling temperature, humidity, and aeration, reducing the traditional composting process from months to just weeks.

The fermented material then moves to the granulation and forming stage. Disc granulators, rotary drum granulator, or extrusion granulators shape the loose material into uniform granules. These granules are not only convenient for storage and application but also enable slow nutrient release in the soil, minimizing loss.

Refinement and Quality Assurance

After granulation, the fertilizer undergoes drying, cooling, and screening. Dryers remove excess moisture to prevent mold; cooling systems rapidly lower the temperature to maintain structural stability; and multi-layer vibrating screens precisely grade the particles to ensure consistent product specifications.

Finally, the automatic packaging system seals the finished fertilizer, applies labels, and prepares it for distribution worldwide. The entire production line is typically equipped with advanced dust and odor removal devices, ensuring a clean and environmentally friendly production environment.

Synergy and Innovation

The strength of a modern bio-organic fertilizer production line lies in the seamless integration of equipment and intelligent control. A central control system monitors the operational status of each stage in real-time, automatically adjusting parameters to ensure stable production efficiency and product quality.

With technological advancements, many production lines now incorporate sensors and data analysis systems, optimizing production processes, reducing energy consumption, and achieving truly green manufacturing.

Sustainable Agriculture in a Global Context

Bio-organic fertilizer production lines are not just a technological achievement; they are a vital pillar of sustainable agriculture. They effectively convert organic waste, reducing environmental pollution while producing high-quality fertilizers that improve soil health and crop quality.

From precision farming in Europe to small-scale farms in Asia, these production lines are adapting to diverse needs at various scales. They represent a model of the circular economy, transforming “waste” into “resources” and contributing to global food security and ecological conservation.

Conclusion: A Bridge Connecting Nature and the Future

The bio-organic fertilizer production line is a crystallization of natural wisdom and human innovation. It respects the principles of natural cycles while leveraging technology to enhance efficiency and effectiveness. In this era of pursuing sustainable development, such production lines are not merely tools for agricultural production but bridges connecting healthy soil, quality food, and a better environment.