Organic Waste Metamorphosis: The Magical Journey of Bio-Fertilizer Production Lines

Have you ever wondered how discarded fruit and vegetable scraps, livestock manure, and other organic waste transform into the “black gold” that nourishes the earth? In the magical factories of bio-organic fertilizer production line, every piece of organic waste undergoes a magnificent rebirth journey. This is not merely an industrial process but a beautiful encounter between nature and technology.

- The Awakening of Waste: From “Useless” to “Treasure”

At an innovative fertilizer plant on the outskirts of Amsterdam, Netherlands, over 50 tons of urban kitchen waste are converted into high-quality organic fertilizer daily. These seemingly useless materials—from coffee grounds to vegetable peels—are broken down into uniform particles through advanced crushing systems. The transformation is so thorough that you can hardly recognize their original forms.

Key Equipment: High-Speed Crushers and Intelligent Sorting Systems

Modern crushing equipment such as cage crusher can not only process various organic materials but also automatically identify and remove impurities like plastics and metals through sensors, ensuring raw material purity.

- The Microbial Feast: Industrial Interpretation of Natural Forces

In a bio-fertilizer plant in Munich, Germany, the fermentation workshop has become a “five-star hotel” for microorganisms. With precisely controlled temperature, humidity, and ventilation systems, it creates an ideal breeding environment for billions of microorganisms. These tiny life forms work diligently in giant fermentation tanks, decomposing complex organic matter into nutrients that plants can directly absorb.

Case Study: Danish Circular Farm

A family farm in Denmark mixes cow manure with straw and, through a closed fermentation system, produces high-quality fertilizer rich in probiotics in just three weeks—80% faster than traditional composting methods.

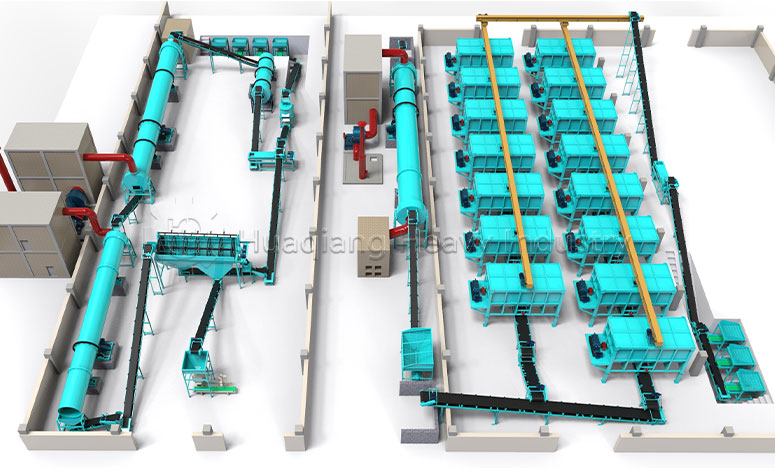

III. The Shaping of Form: The Fusion of Technology and Art

In a modern fertilizer factory in Shandong, China, the granulation workshop showcases industrial beauty. Disc granulator, like giant rotating dancers, shape fermented materials into perfect spherical pellets. These pellets are not only uniform in appearance but also slowly release nutrients in the soil, providing fertilizer effects lasting several months.

Collaborative Equipment Network:

Intelligent Mixing Systems: Precisely proportion various raw materials

Efficient Drying Equipment: Preserve beneficial microbial activity

Precision Screening Machines: Ensure consistent particle size

Automatic Packaging Lines: Process thousands of finished bags per hour

- The Intelligent Revolution: Data-Driven Fertilizer Production

A high-tech fertilizer plant in California, USA, has achieved fully automated production. IoT sensors every production, collecting real-time data and transmitting it to the central control system. Artificial intelligence algorithms analyze this data, automatically adjusting production parameters to ensure each batch of products achieves optimal quality.

Innovation Case: Israeli Precision Fertilization System

An Israeli agricultural technology company developed an intelligent fertilizer production line that can customize the production of organic fertilizers with specific formulations according to different crops, soil types, and growth stages, increasing fertilizer utilization efficiency by over 40%.

- Global Practices: Diverse Success Stories

From large automated factories in Northern Europe to small community projects in Africa, bio-organic fertilizer production lines are changing global agriculture in various forms:

Japanese Urban Farms: In Tokyo’s urban areas, small modular fertilizer equipment converts restaurant kitchen waste into organic fertilizer needed for balcony farms, achieving a true urban circular economy.

Kenyan Smallholder Cooperatives: East African farmer cooperatives use mobile fermentation equipment to convert agricultural waste into organic fertilizer, increasing crop yields by 35% while reducing dependence on imported chemical fertilizers.

Brazilian Sugarcane Industry: South America’s largest sugarcane producer converts bagasse into organic fertilizer, not only solving waste disposal problems but also creating new revenue streams.