Why Large Compost Turners Steal the Show?

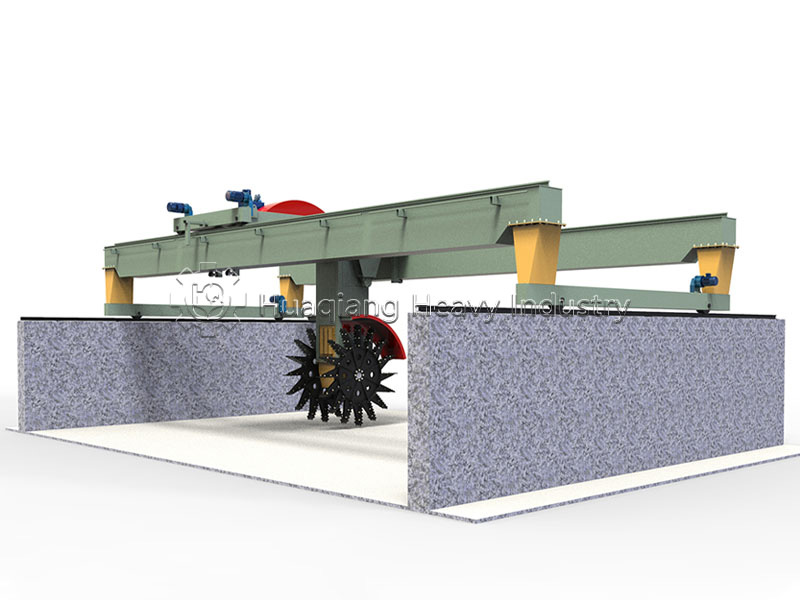

When you step into a modern composting facility, the most striking sight is often the large wheel compost turner—a steel behemoth that moves slowly, its huge wheels digging deep into the material pile, effortlessly turning tons of organic waste. Behind this scene lies a simple yet profound question: why are composting facilities worldwide choosing this equipment as the core of their operations?

The Efficiency Revolution: One Machine Replaces Dozens

At an organic waste processing center in California, USA, a large wheel compost turner can process over 500 cubic meters of material daily—equivalent to the work of 30 laborers simultaneously. This is the primary reason for its popularity: a leap in efficiency.

Key Advantages:

Deep Turning: Handles material piles up to 2.5 meters high, ensuring deep aeration

Uniform Mixing: Powerful mixing capability ensures even blending

Labor Savings: Automated operation reduces manual labor needs by over 70%

Fast Composting: Shortens traditional composting cycles from months to weeks

Quality Assurance: Creating the Ideal Composting Environment

Turning is not just physical mixing; it’s about creating an ideal home for microorganisms. Large wheel compost turners ensure optimal balance of temperature, moisture, and oxygen concentration in the material pile through precise turning frequency and depth control.

Scientific Principle:

Microorganisms require oxygen for aerobic decomposition, generating high temperatures (55-70°C) that kill pathogens and weed seeds. By regularly turning the pile, large turners prevent overheating or excess moisture in the center, promoting uniform decomposition.

Collaborative Operations: The Core Hub of Fertilizer Production Lines

Large wheel compost turners rarely work alone; they integrate closely with the entire fertilizer production line:

Front-end Equipment: cage crusher and sorters preprocess raw materials

Core Equipment: Turners perform biological transformation

Back-end Equipment: Screeners, new type two in one organic fertilizer granulator, and packagers finish product processing

At a composting plant in Munich, Germany, turners with intelligent temperature control systems. When sensors detect abnormal temperatures, the system automatically adjusts turning frequency for precise control.

Success Stories: Diverse Applications from Farms to Cities

Case 1: Large Canadian Farm

A dairy farm in Ontario uses a wheel turner to process mixtures of cow manure and straw. Through precise control, they produce high-quality organic fertilizer, meeting their own needs and generating additional income. The equipment investment paid for itself within 18 months.

Case 2: Japanese Urban Composting Project

A community composting center on the outskirts of Tokyo uses a large wheel turner to process kitchen waste. Its low-noise design and efficient deodorizing system make it suitable for urban environments, processing over 1,000 tons of kitchen waste annually and reducing landfill volume by 30%.

Case 3: Australian Winery

A winery in South Australia uses a turner to process grape pomace and pruning waste. The resulting compost is used in vineyards, improving soil structure and grape quality—a perfect circular economy model.

Economic Benefits: A Wise Long-Term Investment

Although the initial investment in large wheel compost turners is high, the long-term economic benefits are significant:

Lower Operating Costs: Energy costs reduced by 40% compared to manual turning

Improved Product Quality: Uniform compost commands higher market value

Reduced Environmental Impact: Efficient composting reduces methane emissions

Versatile Material Handling: Processes livestock manure, agricultural residues, garden waste, and more